Schneckengetriebemotoren sind ein einzigartiger Motortyp, der für seine kompakte Größe, sein hohes Drehmoment und seinen leisen Betrieb geschätzt wird. Hier finden Sie eine vollständige Anleitung zum Verständnis der Funktionsweise von Schneckengetriebemotoren und ihrer wichtigsten Vorteile.

Was ist ein Schneckengetriebemotor?

Ein Schneckengetriebemotor besteht aus einer Schnecke, die in einem 90-Grad-Winkel mit einem Schneckenrad in Eingriff steht. Die Schnecke hat entlang ihrer Länge spiralförmige Gewindegänge, ähnlich einer Schraube. Wenn der Motor die Schnecke dreht, greifen die spiralförmigen Gewindegänge in die Zähne des Schneckenrads ein und bringen das Rad zum Drehen.

Diese Getriebeanordnung bietet eine hohe Untersetzung auf kompaktem Raum. Das Übersetzungsverhältnis hängt von der Anzahl der Zähne auf dem Rad im Vergleich zur Anzahl der Gewindegänge auf der Schraube ab. Eine eingängige Schneckenschraube mit einem Schneckenrad mit 24 Zähnen würde beispielsweise eine Untersetzung von 24:1 bieten.

Wie funktioniert ein Schneckengetriebemotor?

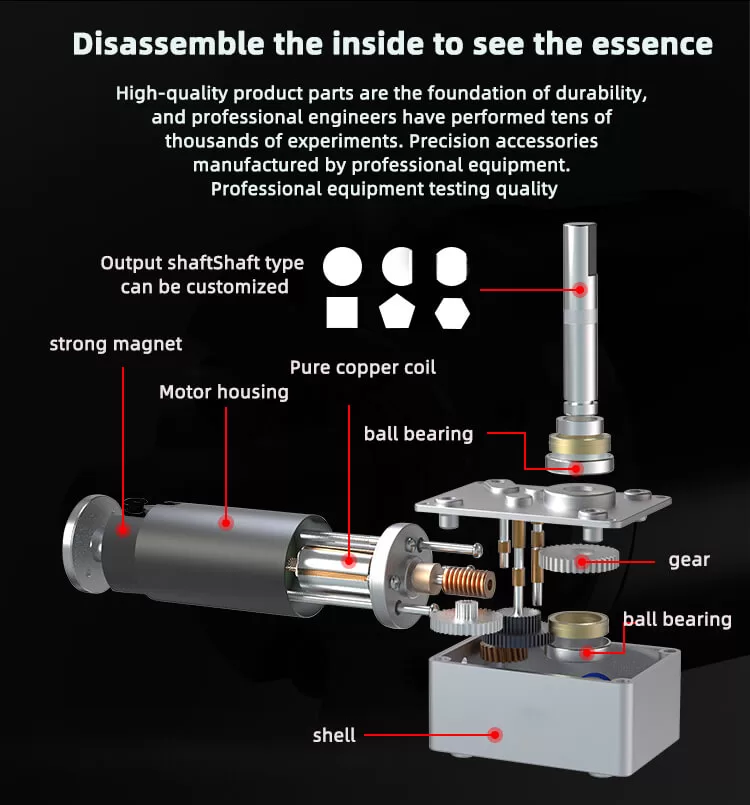

Die wichtigsten Komponenten, die den Betrieb eines Schneckengetriebemotors ermöglichen, sind:

- Schneckenschraube – Die mit dem Motor verbundene Gewindeantriebswelle. Ihr spiralförmiges Gewinde greift in das Schneckenrad ein.

- Schneckenrad – Das Zahnrad, das die Schnecke im 90-Grad-Winkel schneidet. Es hat Zähne, die in das Gewinde der Schnecke eingreifen.

- Übersetzungsverhältnis – Wird durch die Anzahl der Zähne auf dem Rad im Vergleich zum Gewinde der Schraube bestimmt. Sorgt für eine Geschwindigkeitsreduzierung.

Wenn der Motor die Schnecke dreht, rotieren ihre Spiralgewinde gegen die Zähne des feststehenden Schneckenrads. Dadurch dreht sich das Rad langsam, aber mit hohem Drehmoment. Das große Übersetzungsverhältnis ermöglicht die hohe Drehmomentabgabe.

Vorteile von Schneckengetriebemotoren

Schneckengetriebemotoren bieten mehrere entscheidende Vorteile:

- Kompakte Größe – Durch die Verschneidung der Zahnräder im 90-Grad-Winkel entsteht ein äußerst kompaktes Getriebe.

- Hohes Drehmoment – Die große Untersetzung ermöglicht ein hohes Drehmoment aus einem kleinen Motor.

- Wenig Lärm – Der Eingriff von Schnecke und Rad erfolgt geräuscharm.

- Federung – Das Getriebe kann hohe Stoßkräfte aufnehmen.

- Effizienz – Schneckengetriebe übertragen Kraft effizient zwischen sich nicht kreuzenden Wellen.

Häufige Anwendungen

Aufgrund ihrer Vorteile werden Schneckengetriebemotoren in den unterschiedlichsten Anwendungsbereichen eingesetzt:

- Aufzüge – Kompakte Größe und geringe Geräuschentwicklung sind ideal.

- Lebensmittelverpackungsanlagen – Enge Räume erfordern kompakte Getriebemotoren.

- Förderbänder – Hohes Drehmoment in einem kleinen Paket.

- Schweres Gerät – Absorbiert Stoßbelastungen durch das Zerkleinern von Steinen.

- Flughäfen – Gepäckbänder verwenden geräuscharme Schneckengetriebe.

Auswahl des richtigen Schneckengetriebemotors

Bei der Auswahl eines Schneckengetriebemotor, berücksichtigen Sie das erforderliche Drehmoment, die Geschwindigkeit und etwaige Größenbeschränkungen. Hochwertige Motoren von namhaften Herstellern bieten bessere Leistung und Haltbarkeit. Telco ist ein führender Anbieter von Schneckengetriebemotoren, die sich ideal für industrielle Anwendungen eignen, bei denen Zuverlässigkeit erforderlich ist. Wenn Sie immer noch verwirrt sind, den richtigen auszuwählen, hilft Ihnen Faradyi gerne weiter. kontaktiere uns

Wenn Sie verstehen, wie Schneckengetriebemotoren funktionieren und welche Vorteile sie bieten, können Sie den richtigen Motor für Ihre spezifische Anwendung auswählen. Ihre einzigartigen Vorteile machen sie zu einer vielseitigen Wahl für Herausforderungen bei der Kraftübertragung.