Introudution

DC motors are electric motors that run on direct current power. Controlling the speed of a DC motor is essential in many applications to vary motor speed according to requirements and optimize functionality. Speed control allows regulating the movement of motors in devices like vehicles, elevators, and more. There are various methods used to control DC motor speed – both electronically and mechanically. This article will discuss the best ways to control DC motor speed.

Working of a DC Motor

A simple DC motor works by transforming electrical energy into mechanical energy using electromagnetic induction. When current flows through the armature winding, a magnetic field is induced which interacts with the magnetic field from the permanent magnets. This interaction results in a rotational torque which turns the motor.

According to Faraday’s law, the rotating armature motion also induces an opposing EMF. But the supplied voltage overcomes this to sustain rotation. DC motors automatically adjust torque based on load, thanks to this counter EMF effect.

- Varying speed is needed for different materials/applications. For example, drilling materials have optimum speeds.

- In pumping systems, liquid throughput depends on impeller speed.

- Speed control allows optimizing motor function in various conditions.

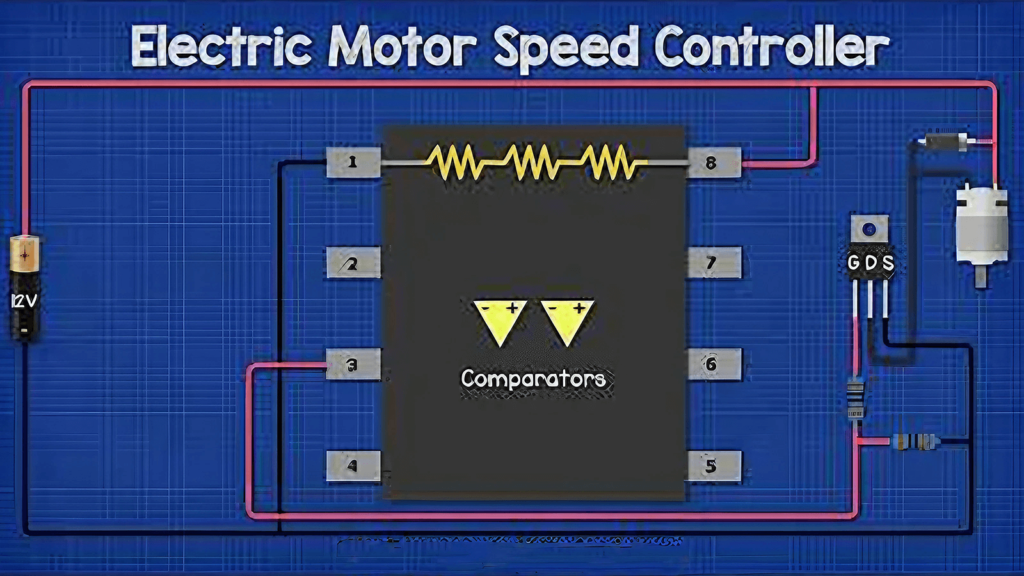

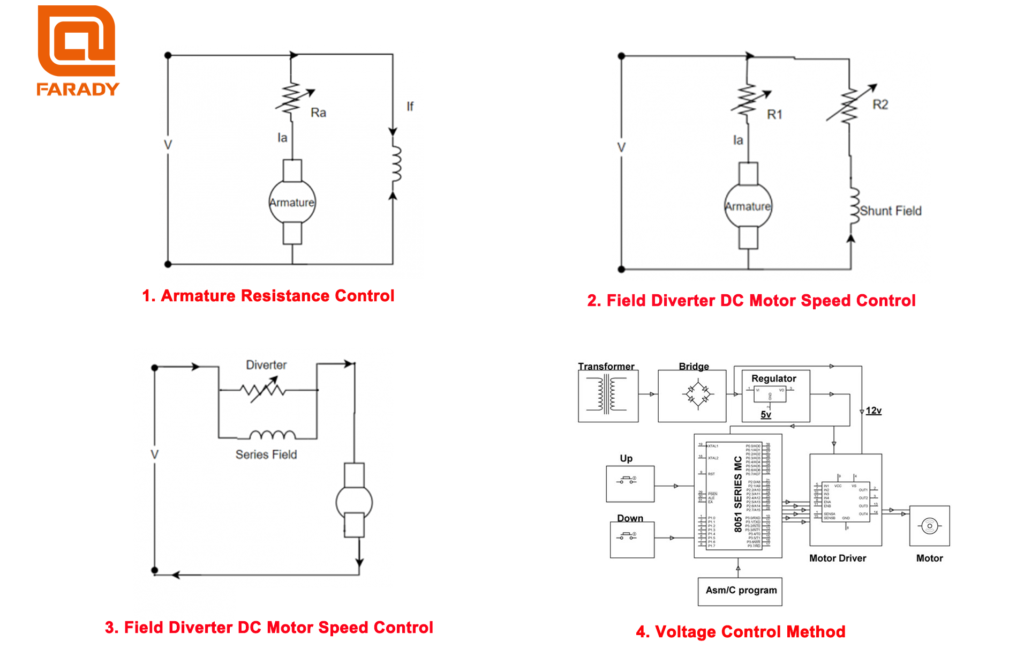

Methods of DC Motor Speed Control

There are different components of the DC motor speed equation which can be varied to change speed. This includes supply voltage, field flux, armature resistance and applied armature voltage. Based on these parameters, various control methods are categorized below:

- Armature Resistance Control

- Field Resistance Control

- Armature Voltage Control

- Flux Control

These methods involve using variable external resistors or power supplies to vary the parameters in the speed equation. Modern electronic methods like PWM control are also popular nowadays.

Conclusion

Controlling the speed is vital for optimizing DC motor performance across various loads and requirements. Both mechanical and electronic design methods are used for DC speed control. The choice depends on factors like required speed range, cost, efficiency etc. Proper control helps utilize DC motors effectively in a wide range of industrial applications.