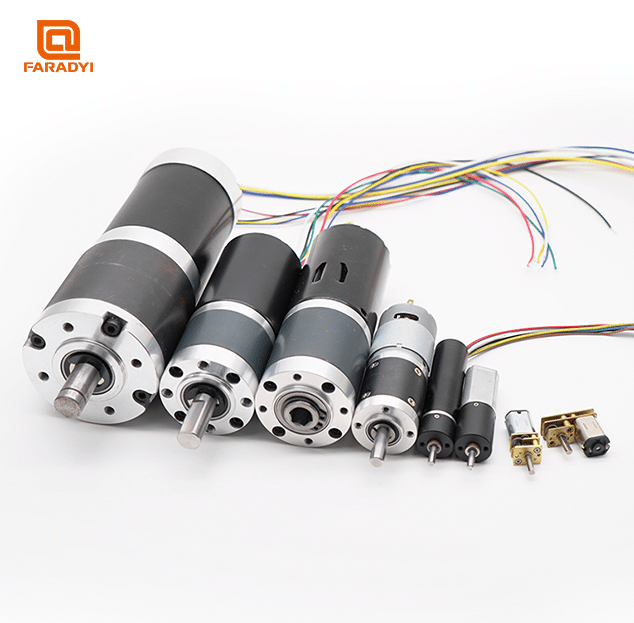

Micro Planetary Gear Motor Factory

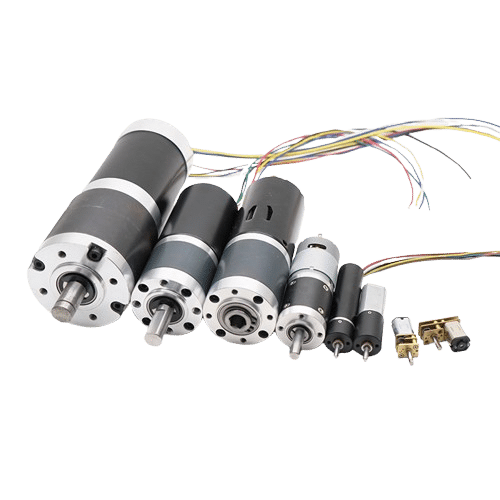

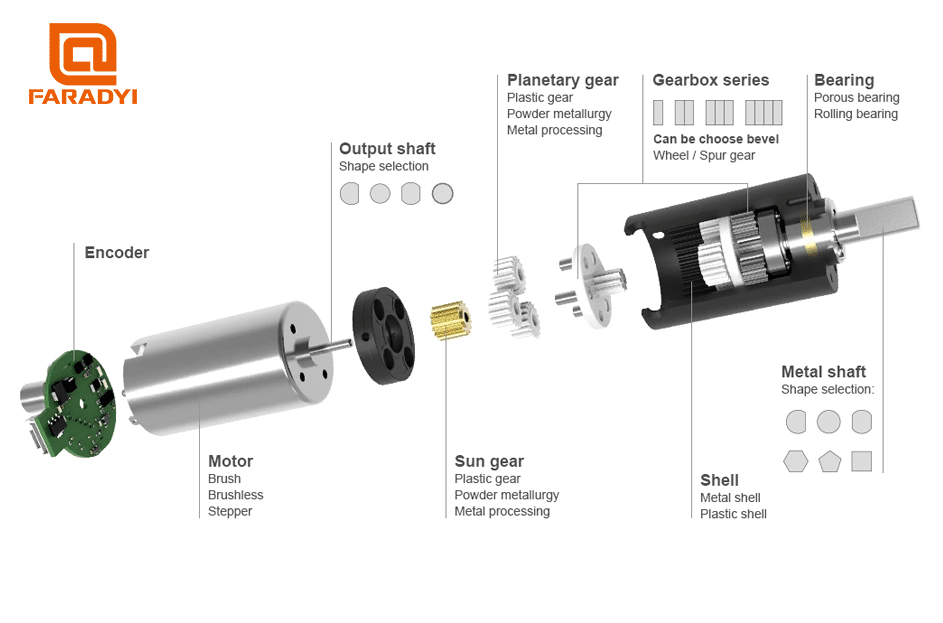

As a leading manufacturer, we specialize in designing and producing micro planetary gear motors available in 12V, 24V, and 36V configurations. Our motors combine planetary gearboxes with brushed or brushless motors, offering a compact design, high efficiency, and exceptional torque output to meet diverse application needs.

Advanced Customization with MIM Technology

Using cutting-edge Metal Injection Molding (MIM) technology, we provide fully motor customizable solutions tailored to the requirements of your industry.

- Diameter Options: 3.4mm, 6mm, 24mm, 28mm, 32mm, 38mm

- Material Choices: Metal or Plastic

- Speed Range: 5 RPM – 100,000 RPM

- Torque Range: 1.0 mNm – 200,000 mNm

Our micro planetary gear motors are engineered for precision, durability, and performance, making them the ideal choice for a wide range of industrial and commercial applications.

The Structure of a Micro Planetary Gear Motor

AC vs. DC Planetary Gear Motors

Choosing between AC and DC planetary gear motors depends on factors such as power source availability, speed control requirements, size constraints, and operational environment.

DC Planetary Gear Motors

- Power Source: Operate on DC electricity, making them ideal for battery-powered applications or systems requiring variable speed control.

- Motor Type:

- Typically use brushed DC motors or brushless DC motors (BLDC).

- BLDC motors are more efficient, quieter, and have a longer lifespan compared to brushed motors.

- Control and Speed:

- Simple control circuits allow for precise speed regulation and quick responsiveness.

- Perfect for applications requiring fine-tuned performance and dynamic speed changes.

AC Planetary Gear Motors

- Power Source: Powered by AC electricity, making them suitable for continuous operation and high-power industrial applications.

- Motor Type:

- Use AC induction motors for robust and reliable performance in continuous operations.

- AC synchronous motors are preferred for applications needing precise speed control.

- Control and Speed:

- Typically require complex control systems.

- Speed regulation is achieved using variable frequency drives (VFDs) or other advanced AC control methods.

- Ideal for applications demanding stable and consistent operation over extended periods.

Summary

DC Motors: Best for portable, battery-powered, or variable-speed applications with simpler control needs.

AC Motors: Ideal for industrial, high-power, or continuous-use scenarios requiring robust performance and advanced speed control.

Selecting the right motor depends on application requirements and operating conditions.

Types of Planetary Gear Motors

Both brushed and brushless planetary gear motors combine high torque, compact size, and the ability to increase motor torque while reducing speed, making them ideal for various applications.

Brushless Planetary Gear Motor (BLDC)

- Commutation: Utilizes electronic commutation with magnets, eliminating the need for brushes.

- Specifications:

- Diameter: 20mm–28mm

- Rated Speed: 5rpm–2000rpm

- Torque: 500mNm–4000mNm

- Advantages:

- Longer lifespan due to reduced wear.

- Low maintenance with no brushes to replace.

- Enhanced speed and torque control for precision applications.

- Applications: Ideal for environments requiring durability, efficiency, and precise control.

Brushed Planetary Gear Motor

- Commutation: Features mechanical commutation using brushes, which wear out over time.

- Specifications:

- Diameter: 6mm–42mm

- Rated Speed: 4rpm–12,000rpm

- Torque: 1mNm–160,000mNm

- Advantages:

- Offers simpler control with less complex electronics.

- Suitable for applications with lower cost requirements.

- Disadvantages:

- Shorter lifespan due to brush wear.

- Requires regular maintenance and brush replacement.

- Applications: Best for applications where cost-efficiency and simple control are priorities.

Faradyi Planetary Gear Motor

FAQs: Planetary Gear Motors

1. What distinguishes a planetary gear motor from a conventional gear motor?

The key difference lies in the gear arrangement and efficiency:

- Planetary Gear Motors:

- Higher torque due to the even load distribution among multiple gears.

- Compact size while delivering high power output.

- Better load distribution, resulting in smoother operation and longer lifespan.

- Conventional Gear Motors:

- Simpler gear arrangements but generally larger and less efficient for the same torque output.

2. How do you select the right planetary gear motor for your application?

The selection process involves evaluating the following factors:

- Torque Requirements: Determine the load and torque needed for the application.

- Speed: Consider the desired input and output speeds.

- Size Constraints: Ensure the motor fits within the available space.

- Efficiency: Choose a motor that meets your energy efficiency needs.

- Load Conditions and Duty Cycle: Assess whether the motor can handle the application’s load and operating duration.

3. Can hydraulic motors with planetary gearboxes be customized?

Yes, hydraulic motors with planetary gearboxes can be customized to meet specific requirements, including:

- Custom Gear Ratios: Tailored to achieve desired speed and torque levels.

- Materials: Selection of materials to suit the operating environment (e.g., corrosion-resistant materials for harsh conditions).

- Mounting Configurations: Adapted to fit unique installation setups.

- Hydraulic Motor Specifications: Adjustments in flow rate, pressure, and displacement.

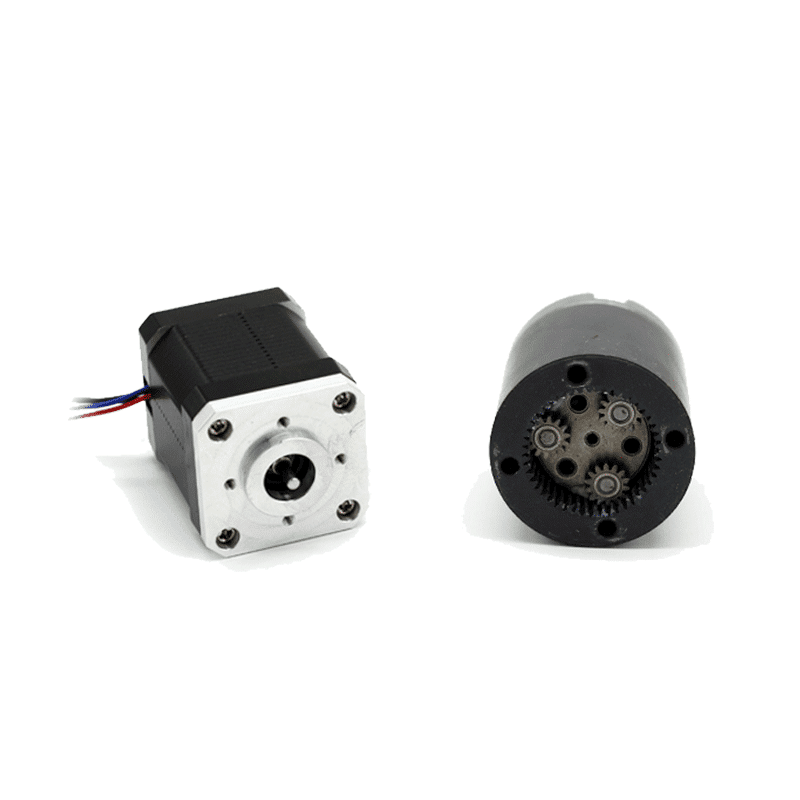

4. What materials are used in the construction of stepper motors with planetary gearboxes?

Common materials include:

- High-Strength Steel: Used for gears and shafts to ensure durability and load capacity.

- Aluminum or Steel: Utilized for motor housings to provide strength and lightweight options.

- Durable Seals and Bearings: Ensure long-lasting performance and resistance to wear.

These materials are selected to deliver reliability, precision, and efficiency in various applications.

Submit a Quick Quote

Don't Take Our Word for It - See What Customers Say

We strive to provide exceptional products and service. If you are satisfied with your experience, we would greatly appreciate you taking a moment to leave us a review