In Memory of a Young Life Lost: A Heartfelt Tribute from Faradyi Motors

At Faradyi Motor, we are deeply saddened and heartbroken by the tragic event that occurred on September 18th, involving a young Japanese boy who lost his life in Shenzhen. As a company with a significant number of our valued customers from Japan, this incident touches us profoundly. We extend our sincerest condolences to the family […]

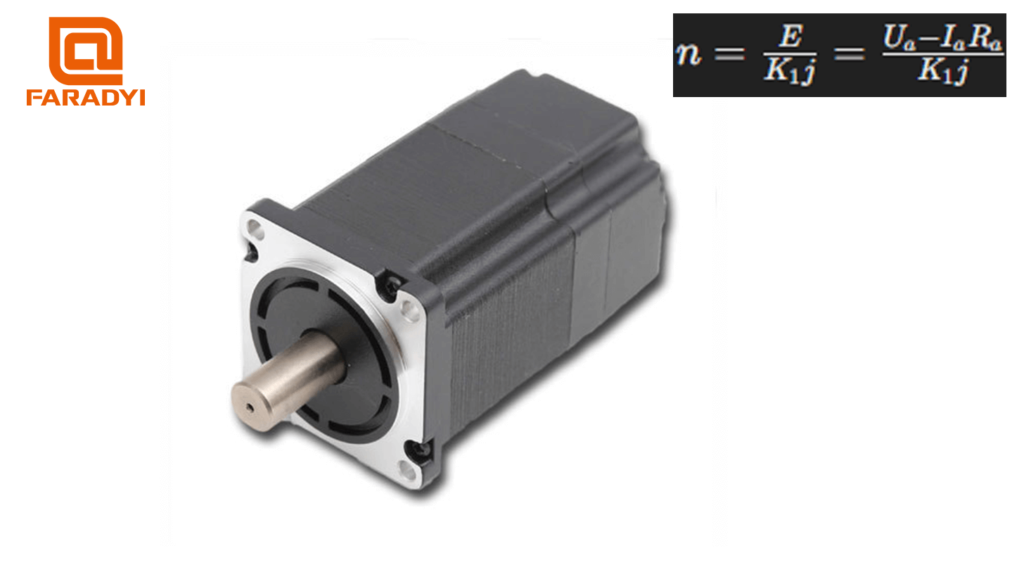

Performance Characteristics Comparison between Low Voltage DC Servo Motors and Stepper Motors

Stepper motors convert electrical pulse signals into corresponding angular or linear displacements. With each input pulse signal, the rotor rotates by a certain angle or moves forward one step. The output angular or linear displacement is proportional to the number of input pulses, and the speed is proportional to the pulse frequency. Therefore, stepper motors act as components that convert pulses into angular (or linear) displacements.

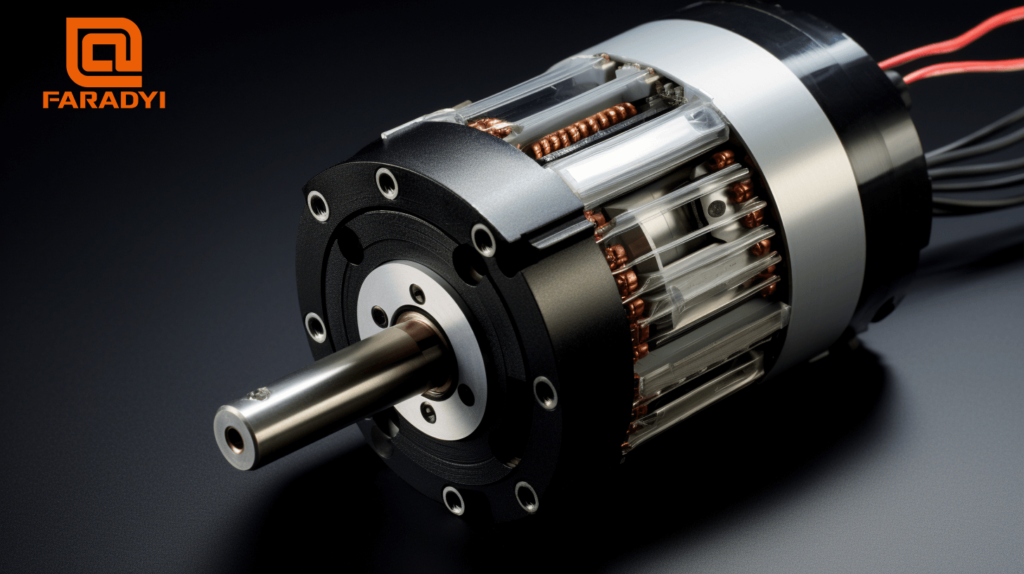

Current Detection in Brushless Motor Drivers

Brushless motor systems require position and current sensors for control. At least two-phase currents are necessary for controlling a three-phase brushless motor. Current sensing can be achieved by detecting the phase currents from the direct current bus, making one sensor sufficient for current control in brushless motors

Analysis of Position Estimation for Brushless DC Motors

Placing the Hall sensors of a brushless DC motor opposite the magnetic wheel formed by the shaft or rotor extension can detect the rotor’s position. However, this only provides enough commutation signals

Basic Knowledge of Brushless DC Motor Systems

Up until now, the majority of people lack awareness of brushless DC motors and drivers, even though they may have encountered them in everyday appliances like air conditioners, washing machines, electric fans, hairdryers, etc.

Types and Characteristics of Stepper Motors

Stepper motors can be classified into three main types based on their structural forms: Variable Reluctance (VR), Permanent Magnet (PM), and Hybrid Stepping (HS) motors. The operational performance of stepper motors is closely related to their control methods, which can be categorized into three types:

Reasons for Stepper Motor Stalling

When a stepper motor becomes stuck, it indicates insufficient torque even when the motor and its driver are undamaged. When the stepper motor is fixed in place, the primary factors affecting torque are speed and current

Choosing the Number of Phases for Stepper Motors

When selecting a stepper motor, it’s crucial to consider the advantages and disadvantages of various motor types. Let’s explore the pros and cons of stepper motors with different phase numbers:

Correct Installation of Planetary Gear Reducers

Planetary gear reducers are widely used in the transmission systems of control motors such as servo motors, stepper motors, and brushless DC motors due to their high precision, small size, high transmission efficiency, and wide range of reduction capabilities.

Factors Affecting the Efficiency of Planetary Gearboxes

During the operation of a planetary gearbox, its iron core is subjected to alternating magnetic fields, resulting in iron losses. Additionally, the motor winding, when energized, generates copper losses along with other associated losses.