Reasons and Solutions for Brushless Motors Failing to Start

Low Power Supply Voltage or Excessive Voltage Drop during Startup:

If the power supply voltage is too low, investigate the root cause.

If excessive voltage drop occurs during startup, consider raising the startup voltage. For systems using autotransformer starting devices, adjusting the tap position can increase the startup voltage.

Solutions for Overheating in Two-Phase Four-Wire Stepper Motors

The two-phase four-wire stepper motor, as a digital actuator, has found widespread applications in motion control systems. Many users may experience significant heating when using the two-phase four-wire stepper motor

Maintenance Tips for Hybrid Stepper Motors

The hybrid stepper motor is designed by integrating the advantages of permanent magnet and variable reluctance stepper motors. It is further divided into two-phase, three-phase, and five-phase hybrid stepper motors, with a typical step angle of 1.8° for two-phase, 1.2° for three-phase, and 0.72° for five-phase.

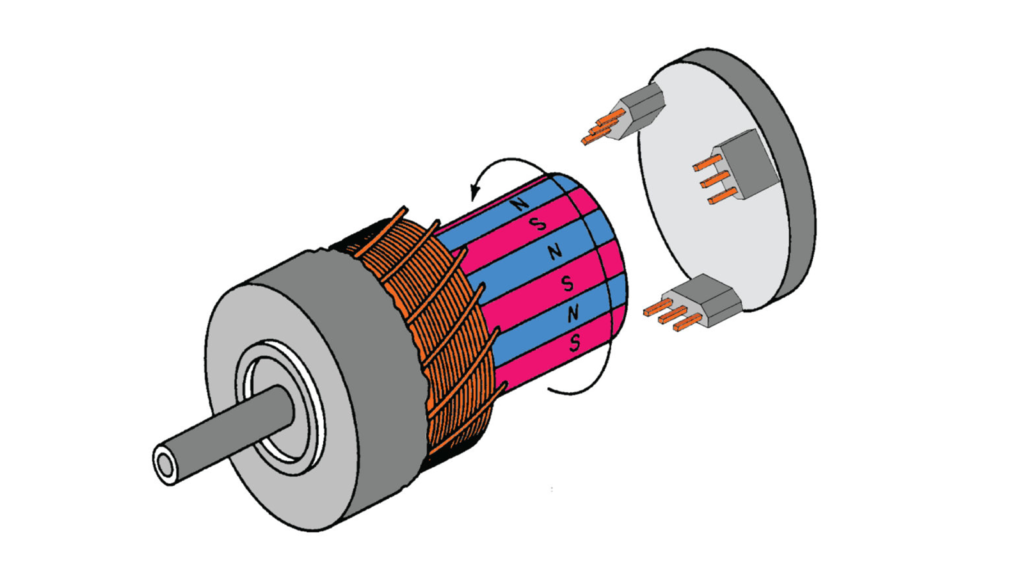

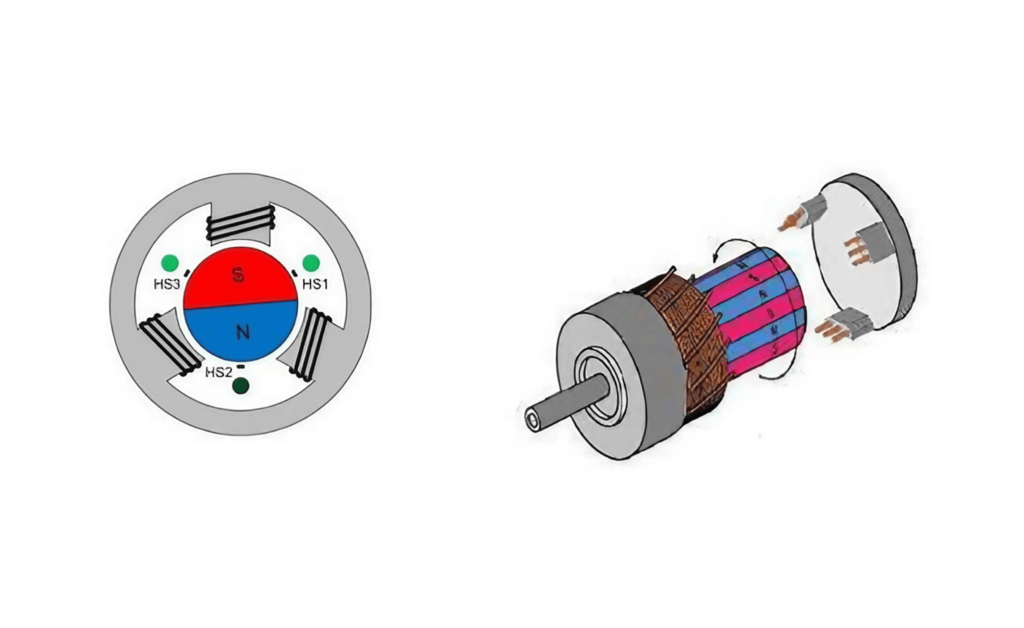

Analysis of Pole Pairs in Brushless Motors

The pole pairs of a brushless motor are determined by detecting changes in the magnetic field of the rotor. The rotor magnetic steel is arranged alternately as N-pole and S-pole. When the Hall sensors of the brushless motor detect a transition from N-pole to S-pole or from S-pole to N-pole, the Hall’s output undergoes corresponding high and low level changes, indicating a change in the rotor’s position

Analysis of Silicon Steel Sheets in Brushless Motors

The rotor of a brushless motor consists of two parts: an internally composed rotor core made of silicon steel sheets and a surface-mounted permanent magnet. This is the surface-mounted permanent magnet structure.

Applications of High-Power Brushless DC Motors in the Automotive Industry

High-power brushless DC motors find various applications in the automotive industry, primarily in wheel drive, air conditioning compressors, air conditioning blower fans, purifiers, exhaust fans, and more. Let’s explore these applications further with insights from Faradyi Motors: These are the applications of high-power brushless DC motors in the automotive industry. We hope this information provides […]

Analysis of Gain Adjustment in DC Servo Motor Controllers

DC servo motor controllers involve various gain adjustments to optimize performance. Faradyi Motors will break down these adjustments

The Role of Encoders in Closed-Loop Control of Low-Voltage DC Servo Motors

In the realm of industrial automation, the closed-loop control system for low-voltage DC servo motors is a pivotal technology. In layman’s terms, “closed-loop” signifies a continuous cycle where the motor receives instructions and provides corresponding responses. This interaction is characterized by digital commands and data-driven responses.

Distinguishing Between Absolute and Incremental Encoders in DC Servo Motors

DC servo motor encoders are rotational sensors that convert rotary displacement into a series of digital pulse signals. These pulses play a crucial role in controlling angular displacement, and when coupled with gear racks or screw threads, they can also be utilized for linear displacement measurements. DC servo motor encoders fall into two main categories: […]

Why Brushless Motors Require Position Sensors: A Comprehensive Guide

If you’re acquainted with using brushless motors, you’re likely familiar with the concept of position sensors. However, the precise role of these sensors might be less clear. In the realm of brushless motors, position sensors play a crucial role in measuring the rotor pole’s position, providing accurate commutation information to the logic switch circuit—essentially converting […]