Introduction

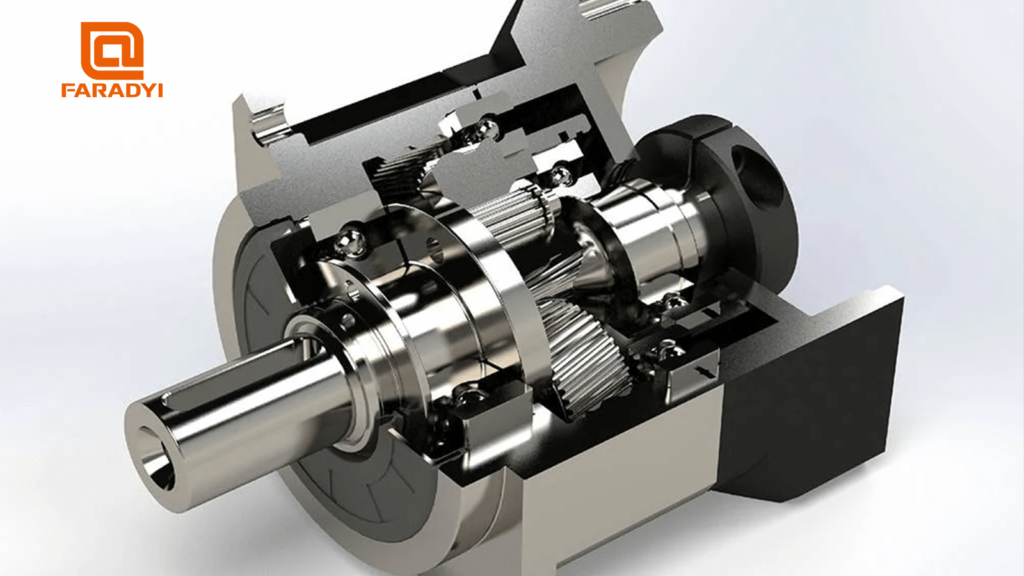

A 3-stage planetary gearbox has three sets of planetary gears inside, providing greater reduction ratios, output torque, efficiency, and precision compared to single or 2-stage gearboxes. Here’s an overview of what 3-stage gearboxes are and their key advantages.

Key Advantages:

1. Higher Reduction Ratios:

With three sets of planetary gearsets, 3-stage gearboxes achieve much greater reduction ratios, exceeding 100:1 in many cases. This allows translation of higher input speeds into usable low output speeds.

2. Increased Torque Capacity:

The additional gear stages allow 3-stage gearboxes to handle substantially higher torque loads versus 1 or 2 stage versions. This makes them well-suited for applications requiring both slow, precise motion and high torque output.

3. Improved Efficiency

While an extra gear stage can lower efficiency, advanced 3-stage gearbox designs optimize internal power transmission and minimize losses across each stage, resulting in excellent cumulative efficiency.

4. Enhanced Precision

Minimal flutter or variance in output speed/torque translates to superior motion precision in 3-stage gearboxes. The multi-stage design dampens effects of individual gear fluctuations.

5. Compact Size

Smart engineering allows major brands to construct 3-stage gearboxes in impressively small packages, saving space and weight.

Conclusion

If extreme gear ratios, high torque capacity, and exceptional efficiency are critical application requirements, a meticulously-designed 3-stage planetary gearbox is an optimal choice. The extra complexity pays dividends across critical performance parameters.