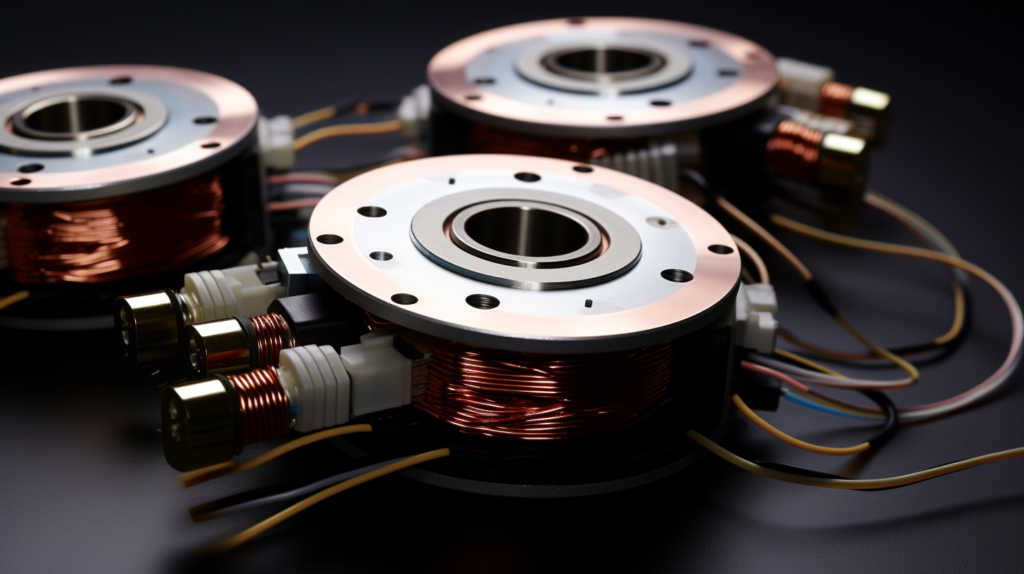

In the usage of permanent magnet brushless motors, the most significant risk is demagnetization caused by high temperatures. It is well-known that the critical component of permanent magnet brushless motors is the magnetic steel, and magnetic steel is highly susceptible to temperature. Prolonged exposure to high temperatures gradually leads to demagnetization, with the risk increasing as the temperature rises. Once demagnetization occurs at an alarming rate, the motor’s current continues to increase, resulting in higher energy consumption. This raises the user’s electricity costs and poses the possibility of the motor shutting down at any moment. Once a permanent magnet brushless motor experiences demagnetization, replacement is often the only option, incurring substantial maintenance costs. How can demagnetization in permanent magnet brushless motors be detected, and what preventive measures can be taken?

Causes of Demagnetization in Permanent Magnet Brushless Motors:

The performance of permanent magnet brushless motors is characterized by an essential indicator, the high-temperature resistance level. Exceeding this temperature resistance level causes a sharp drop in magnetic flux density. High-temperature resistance levels include: N series (80 degrees Celsius), M series (100 degrees Celsius), H series (120 degrees Celsius), SH series (150 degrees Celsius), UH series (180 degrees Celsius), and EH series (200 degrees Celsius).

- Inadequate heat dissipation in permanent magnet brushless motors leading to excessive motor temperatures.

- Lack of a temperature protection device in permanent magnet brushless motors.

- Excessive ambient temperatures.

- Poorly designed motor.

Preventive Measures by Permanent Magnet Brushless Motor Manufacturers:

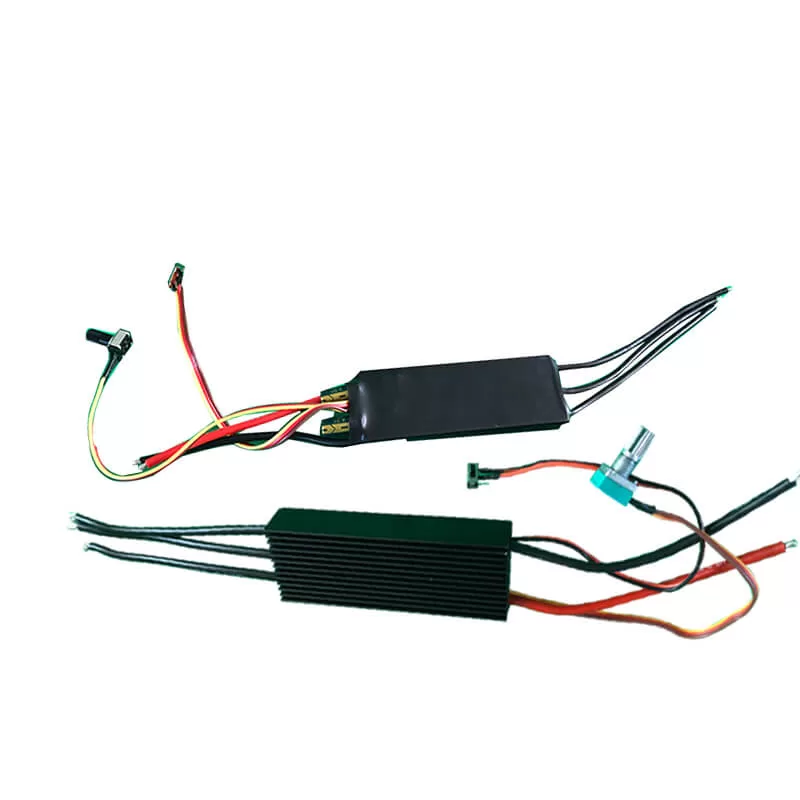

Accurate Selection of Permanent Magnet Brushless Motor Power

Demagnetization is related to the power selection of the motor. Accurately choosing the power of the permanent magnet brushless motor can prevent or delay demagnetization. Overheating is a significant cause of demagnetization, and overloading is the primary reason for overheating.

Therefore, when selecting motor power, a certain margin should be left, typically around 20%, depending on the actual load.

Avoid Heavy Load Starting and Frequent Starts

Understanding the correct methods to prevent demagnetization in permanent magnet brushless motors can reduce future maintenance costs.

Choose Magnetic Steel with High-Temperature Resistance

Opt for magnetic steel with high-temperature resistance levels to reduce the risk of demagnetization, ensuring a safer and more reliable operation.