DC motors are electric motors that are powered by direct current. Features include the ability to run at high speeds, and high starting torque. They can broadly be divided into two groups. This page provides a simple introduction to the brushed DC motor and how they work.

Understanding Brushed DC Motors: The Basics

Brushed DC motors, a fundamental component in various mechanical systems, play a pivotal role in converting electrical energy into mechanical motion.

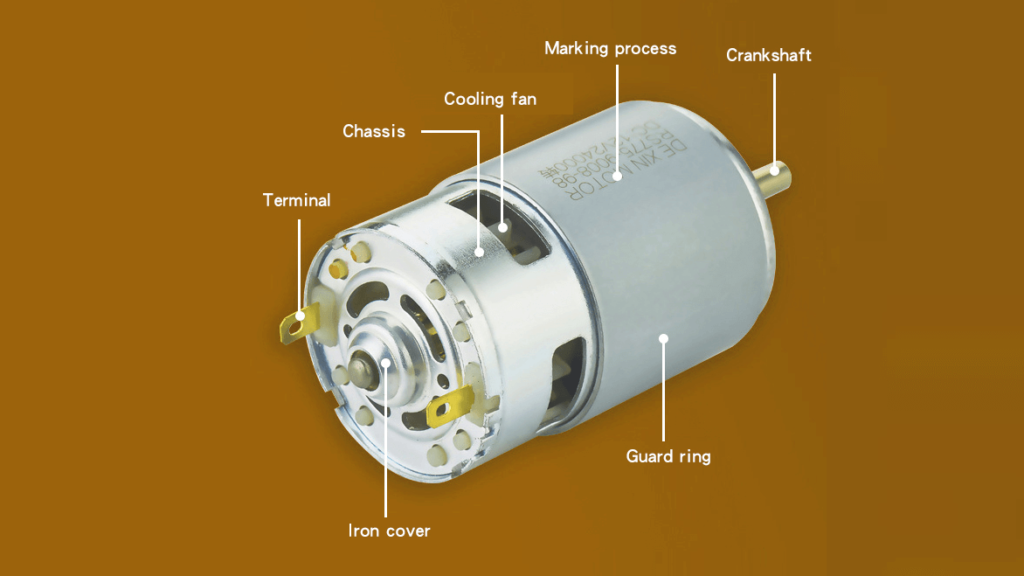

At the core of a brushed DC motor’s operation lies a simple yet ingenious mechanism. The motor consists of two main parts: the stator and the rotor. The interaction between these components creates the driving force behind the motor’s operation.

When an electrical current flows through the coils on the rotor, it generates a magnetic field. This field interacts with the stationary magnets on the stator, causing the rotor to turn.This reversal of current sustains the rotor’s movement in a single direction.

The Importance of Regular Maintenance

Despite their effectiveness, brushed DC motors demand consistent maintenance to retain their efficiency and extend their lifespan. The brushes, crucial for transferring electrical current between the stationary and rotating parts of the motor, are subject to wear over time. This wear leads to increased friction, reduced efficiency, and potential performance issues.

Regular maintenance routines encompass several tasks that collectively contribute to the motor’s reliability:

Brush Inspection and Replacement

Cleaning the commutator, often prone to debris accumulation, ensures smooth and uninterrupted current transfer.

Alignment and Balancing

Correct alignment and balancing of the motor’s components prevent excessive vibration, enhancing both performance and longevity.

Electrical Testing

Regularly testing the motor’s electrical parameters helps identify any deviations from optimal performance and allows for timely adjustments.

Conclusion

Brushed DC motors are an integral part of various applications, from household appliances to industrial machinery. Understanding their operational principles and recognizing the significance of regular maintenance is essential for ensuring their sustained performance. By implementing a proactive maintenance regimen, individuals and industries can reap the rewards of enhanced efficiency, prolonged lifespan, and consistent operation from these reliable workhorses of the mechanical world.