Brushless DC (BLDC) motors are growing in popularity due to their high efficiency, low maintenance requirements, and controllable speed. But how do these electronically commutated motors work without brushes and commutators?

What’s Inside a BLDC Motor?

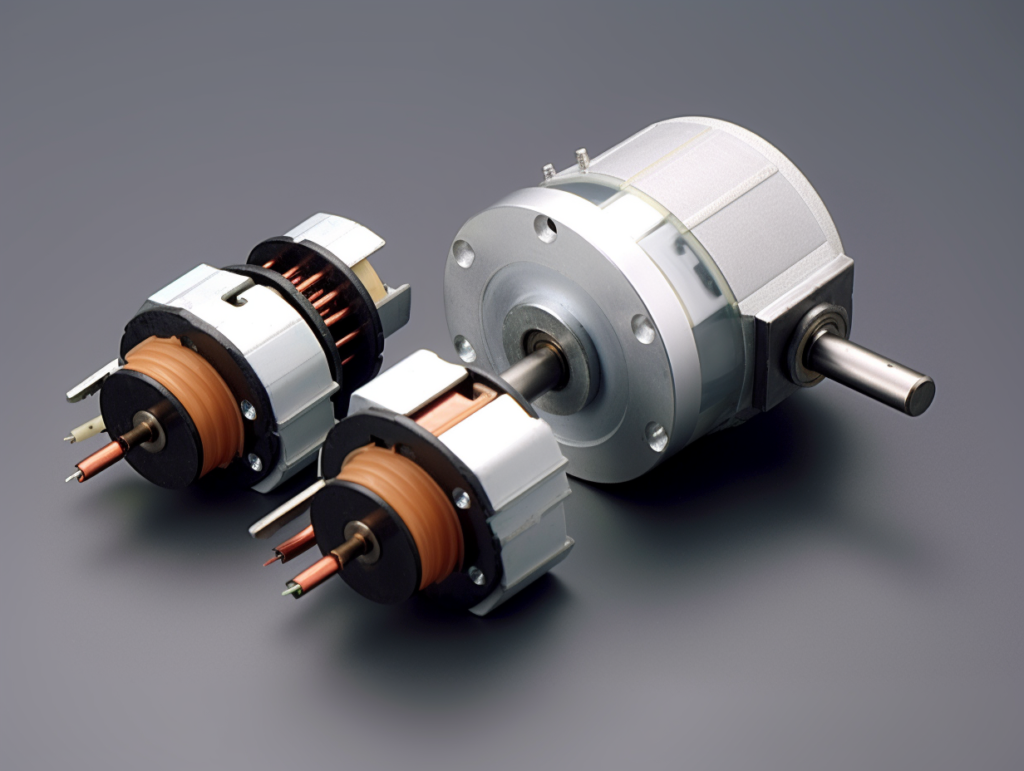

A brushless DC motor contains two main components – a stator and a rotor:

-

- The stator is the stationary part made up of stacked steel laminations with winding coils around it.

-

- The rotor is the rotating part containing permanent magnets.

There are also hall effect sensors to detect the rotor’s position and feed this info to the electronic speed controller.

The Electronic Commutation System

BLDC motors replace the brushes and commutator contacts found in brushed DC motors with an intelligent electronic controller. This electronic circuitry switches current to the stator coils in the correct sequence to rotate the magnetic field.

The hall effect sensors identify the position of the permanent magnet rotor at any given time. Based on the rotor’s position, the controller energizes the stator coils to attract or repel the rotor magnets and keep it spinning.

By controlling the timing and sequence of stator currents, the electronic controller system allows precise and efficient operation without sparking and wear issues of brushes.

Advantages of Brushless Operation

Some key benefits of brushless operation include:

- Increased motor life span – No brush or commutator erosion

- Reduced electromagnetic interference – No sparking from brushes

- Higher speed operation possible – Electronic commutation can switch currents faster

- Higher efficiency – No energy wasted generating sparks

- Cooler running – Heat generation reduced without sparking brushes

- Lower acoustic noise – Eliminates audible brush sparking

- Higher power density – Compact size versus brushed motors

Applications of BLDC Motors

Brushless DC motors are ideal for applications like:

-

- Electric vehicles – EVs, e-bikes, drones

-

- Robotics – For precise position and speed control

-

- Medical equipment – MRI machines, dental tools

-

- Home appliances – Fans, vacuums, washing machines

-

- Computer peripherals – Disk drives, printers

Understanding how BLDC motors work helps explain why they are replacing brushed DC motors across many industry applications. The electronic commutation and control enables high performance with minimal maintenance needs.

For More about the BLDC Motors Details or question about BLDC motors, we are willing to help, just Contact Us.