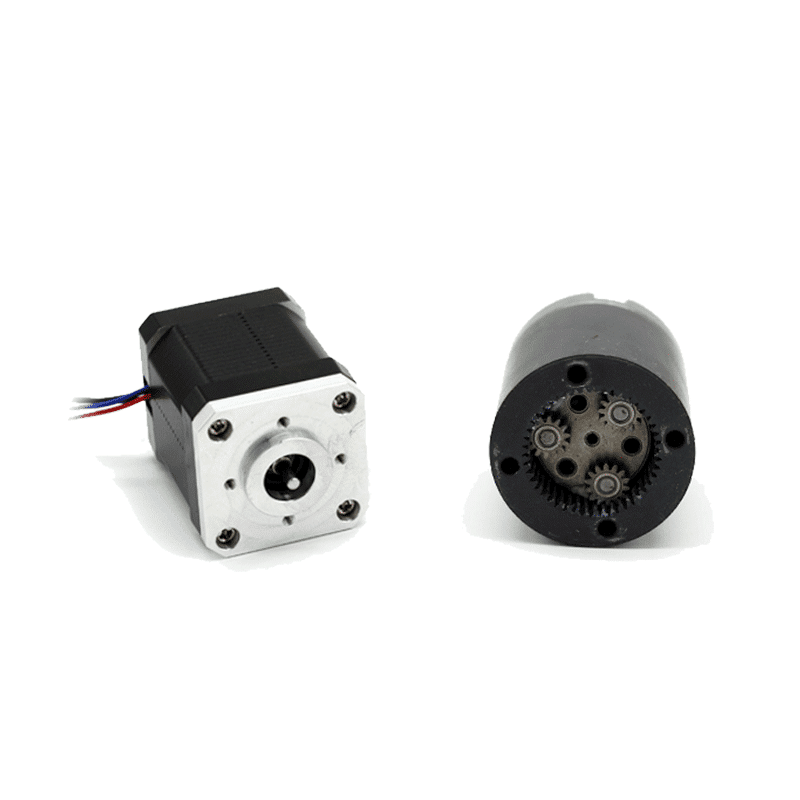

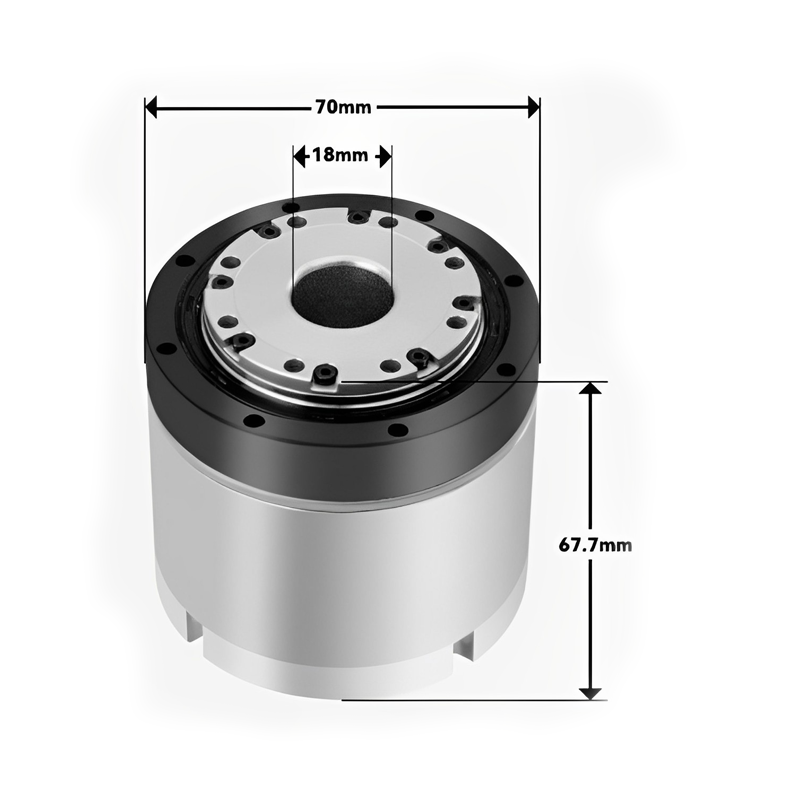

The hybrid stepper motor is designed by integrating the advantages of permanent magnet and variable reluctance stepper motors. It is further divided into two-phase, three-phase, and five-phase hybrid stepper motors, with a typical step angle of 1.8° for two-phase, 1.2° for three-phase, and 0.72° for five-phase.

Hybrid stepper motors, as digital actuators, find widespread applications in motion control systems. Many users may notice significant heating when using hybrid stepper motors, raising concerns about whether this phenomenon is normal. In reality, heating is a common occurrence in hybrid stepper motors, but understanding what degree of heating is considered normal and how to minimize it is crucial.

-

Understanding Why Hybrid Stepper Motors Heat Up:

- To comprehend why hybrid stepper motors generate heat, one must understand the structure and principles of these motors. Hybrid stepper motors consist of a core and winding coils. The winding coils have resistance, and powering them results in losses proportional to the square of the current and resistance, known as copper losses. Additionally, there are hysteresis and eddy current losses in the core due to the magnetic field variations, known as iron losses. Both copper losses and iron losses contribute to heating, affecting the motor’s efficiency. Hybrid stepper motors, which prioritize positioning accuracy and torque output, often have lower efficiency, higher current, and significant harmonic components, resulting in noticeable heating compared to typical AC motors.

-

Heating Varies with Speed in Hybrid Stepper Motors:

- When employing constant current drive technology, hybrid stepper motors maintain relatively constant current during static and low-speed operation to ensure constant torque output. As the speed increases to a certain extent, the internal counter-electromotive force rises, causing the current to gradually decrease, and consequently, the torque decreases. Therefore, the heating due to copper losses is speed-dependent, being higher at static and low speeds and lower at high speeds. However, the situation is not as straightforward for iron losses, and the overall heating is the sum of both.

-

Keeping Hybrid Stepper Motor Heating within a Reasonable Range:

- The acceptable level of heating in hybrid stepper motors primarily depends on the motor’s internal insulation class. The internal insulation withstands high temperatures (above 130 degrees) before breaking down. As long as the internal temperature stays below 130 degrees, the hybrid stepper motor remains undamaged, and at this point, the surface temperature typically stays below 90 degrees. Therefore, surface temperatures of 70-80 degrees are considered normal. Simple temperature measurement methods include using a point thermometer or making rough judgments: if you can touch it for 1-2 seconds, it’s likely below 60 degrees; a quick touch indicates approximately 70-80 degrees; and if a few drops of water vaporize rapidly, it’s likely above 90 degrees. Of course, a temperature gun can also be used for more accurate measurement.

-

Reducing Heating in Hybrid Stepper Motors:

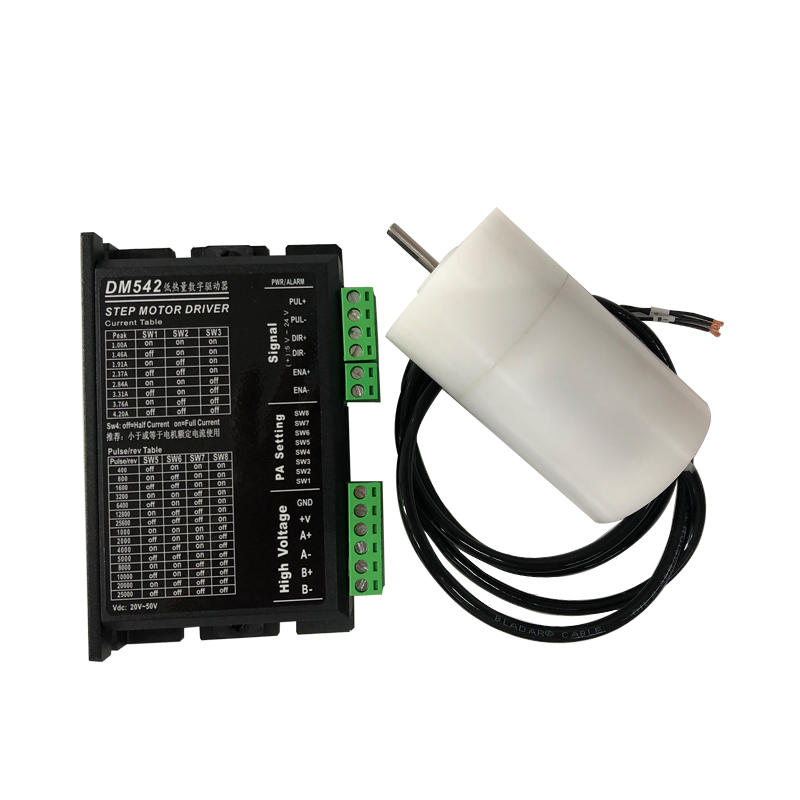

- To minimize heating in hybrid stepper motors, efforts should be made to reduce both copper losses and iron losses. Reducing copper losses involves selecting motors with lower resistance and rated current when possible. For two-phase motors, series-connected motors should be used instead of parallel-connected motors, although this might conflict with torque and high-speed requirements. For already selected hybrid stepper motors, it’s essential to leverage the automatic half-current control and offline functions of the driver. The former automatically reduces the current when the motor is static, and the latter cuts off the current completely. Additionally, using microstepping drivers results in a current waveform closer to sine waves, reducing harmonic losses and, consequently, motor heating. Reducing iron losses is more challenging, as it depends on factors like voltage level. High-voltage drive motors enhance high-speed characteristics but also increase heating. Therefore, choosing an appropriate drive voltage that balances high-speed performance, smoothness, and heating is crucial.

-

Impacts of Excessive Heating in Hybrid Stepper Motors:

- While heating generally does not affect the lifespan of hybrid stepper motors and may not be a concern for most users, severe heating can have some negative effects. The varying thermal expansion coefficients of different parts inside the motor can induce structural stress changes and minor changes in internal clearances, impacting the motor’s dynamic response. High-speed operation may become prone to losing steps. In situations where excessive heating is not permissible, such as medical equipment and high-precision testing devices, controlling motor heating is essential.

In conclusion

this provides comprehensive insights into maintenance tips for hybrid stepper motors. Faradyi Motors specializes in the research and development of brushless motors, DC servo motors, stepper motors, and various matching controllers, offering professional technical support.