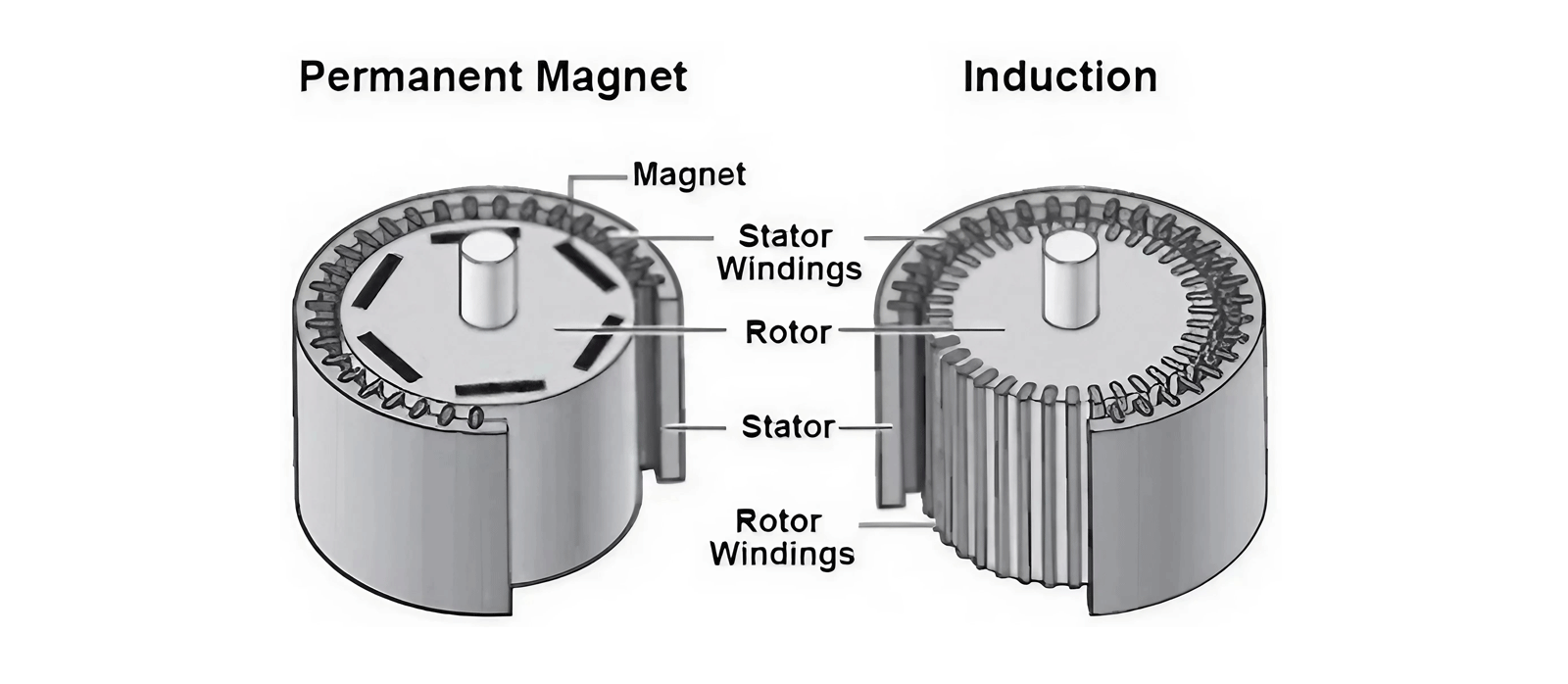

The choice between a permanent magnet (PM) motor and induction motor is crucial for many applications requiring high efficiency and performance. With electrification accelerating across industries, understanding the key differences between these two motor types is critical.

PM motors offer higher efficiency and torque density compared to induction motors. However, induction motors have historically been more widely available and cost effective. Recent advances in PM materials like neodymium magnets have made PM motors more viable for a range of uses.

Let’s compare PM and induction motors on factors like efficiency, torque production, speed control, cost, and materials.

Efficiency and Torque Density Advantages of PM Motors

-

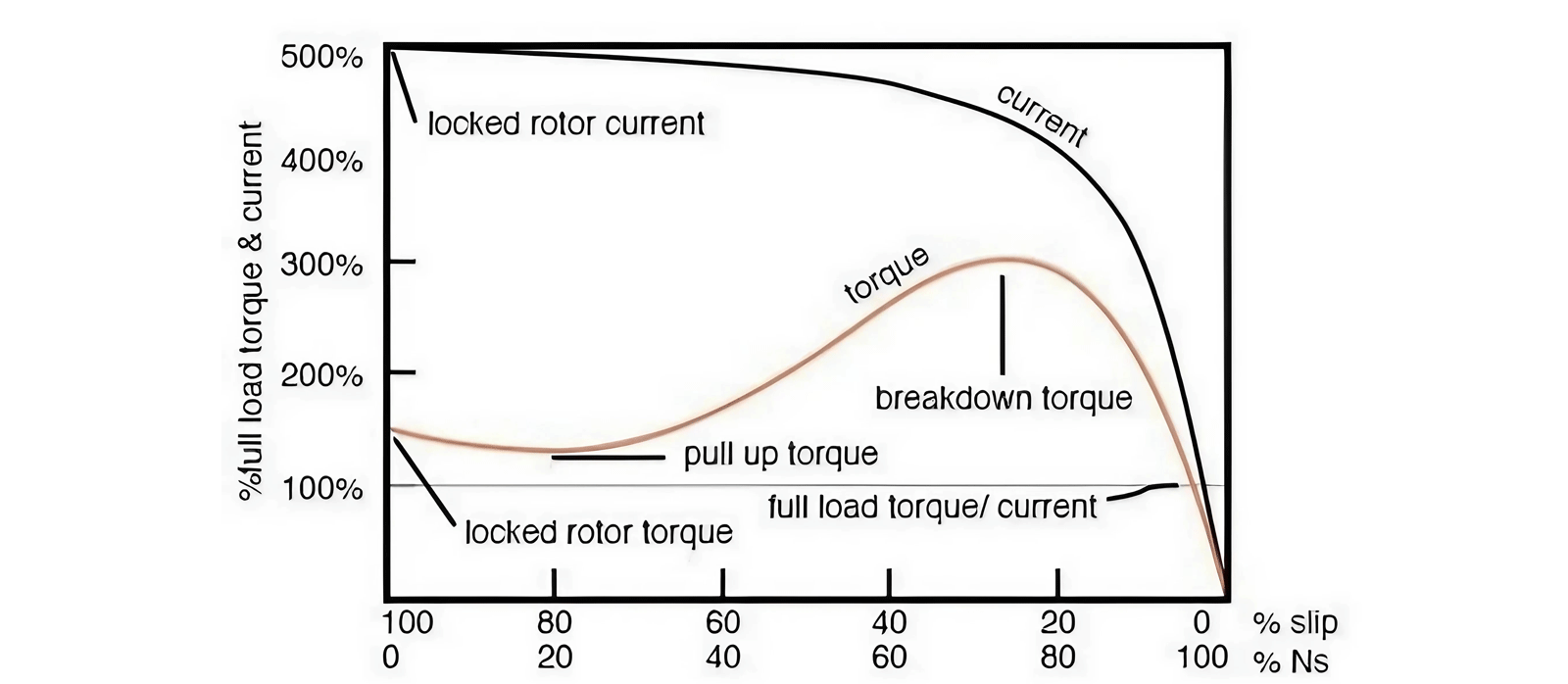

- PM motors have inherent synchronous operation, eliminating lag between rotor and stator. This allows for efficiency ratings up to 97.5%.

-

- Induction motors limited to 90-93% efficiency due to required slippage between applied stator current and resulting rotor field.

-

- PM motors offer higher torque density – more torque per weight. A 50 kW PM motor weighs under 30 lbs versus a 75 HP induction motor over 500 lbs.

Speed Control and Frequency

- PM motors operate synchronously at the applied frequency, enabling precise variable speed control.

- Induction motors cannot reach synchronous speed due to required slippage. At 60 Hz, ~5% speed loss. Limits speed control flexibility.

Cost Considerations

- PM motor magnets like neodymium are more expensive. Opportunity to use powdered metal to offset cost.

- Induction motors use readily available silicon steel laminations, keeping costs down.

Materials and Manufacturing

- PM rotor and stator can be powder metal, avoiding lamination waste. Soft magnetic composites (SMCs) enable lower losses at high frequencies.

- Induction motor rotors and stators traditionally use laminated silicon steel.

- Powder metal allows 3D shaping to eliminate end turn losses in PM motors. More efficiency gains.

Conclusion:

With higher efficiency, precise speed control, and lighter weight, PM motors are superior to induction motors for applications like EVs, battery tools, and variable speed drives. The use of powdered metal helps improve PM motor performance and cost efficiency. Recent advances in PM materials have helped make PM motors viable replacements to induction motors across industries pursuing electrification.