- (+086) 18923470557

- [email protected]

- 7F, No.53 Fofu Road, Dalang Town, Dongguan City, Guangdong, CN,523770

Faradyi Motors Service

Tiny and Precise

Outer diameter: 142mm

Length: 133.9mm

Weight: 6.7kg

Max.Torque: 892N·m

Max.Speed: 40RPM

| Actuator Series | Faradyi Rob I Series |

| Outer Diameter | Φ 142 mm |

| Length & Load | High Torque Strain Wave Gear |

| Gear Ratio | Gear Ratio: 50 |

| Gear Ratio: 80 | |

| Gear Ratio: 100 | |

| Gear Ratio: 120 | |

| Gear Ratio: 160 | |

| Model | I Type |

| T Type | |

| Brakes | Free Motion |

| With Brakes | |

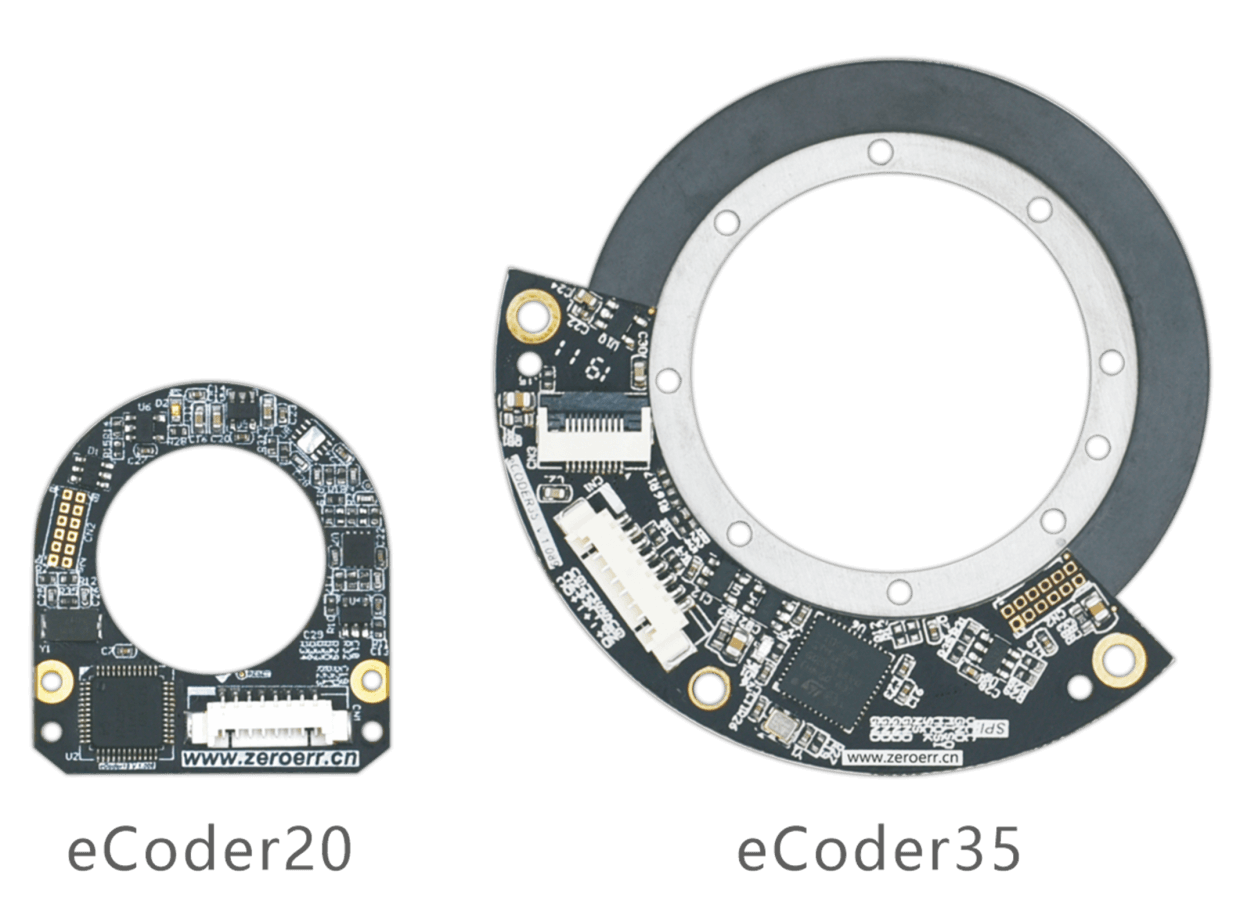

| Encoder | Singleturn Encoder |

| Multiturn Encoder | |

| High Precision calibrated Singleturn Encoder | |

| High Precision calibrated Multiturn Encoder | |

| Inner Diameter | 18mm |

| Communication Protocol | EtherCAT |

| CANopen | |

| Virtual Torque Sensor | Virtual Torque Sensor |

| No Virtual Torque Sensor | |

| Grease | C-means the use of low temperature grease. |

Thanks for sharing it !

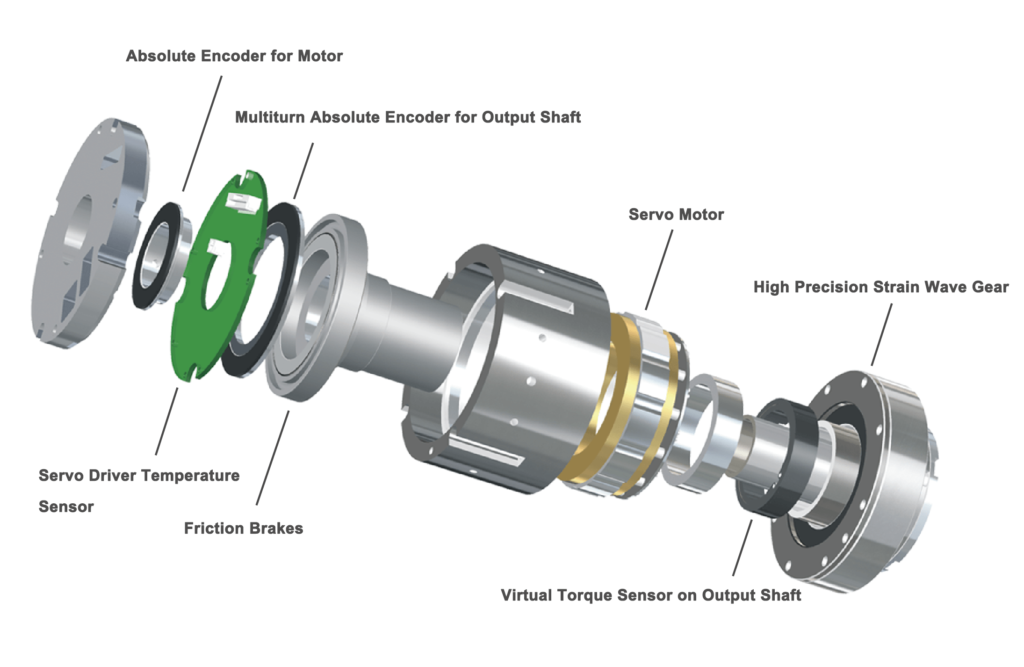

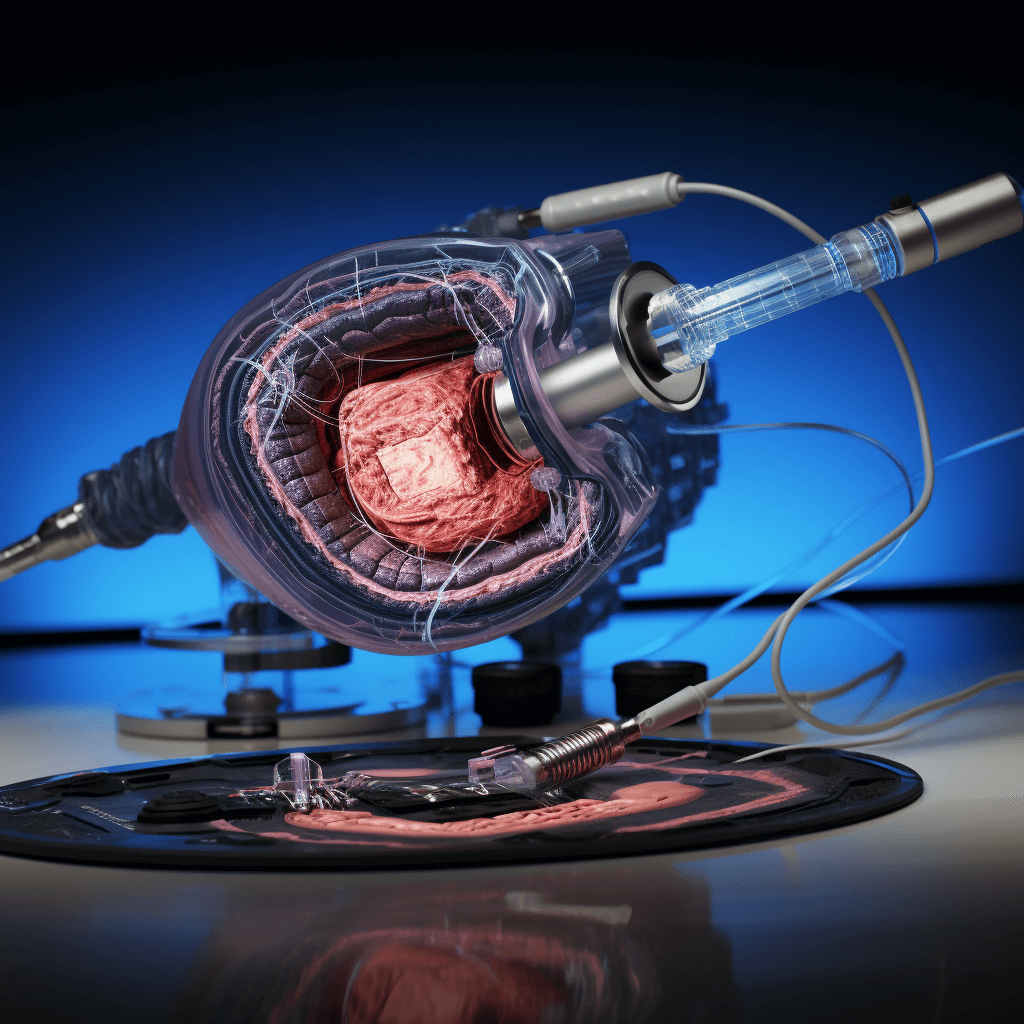

Meet the Faradyi Rotary Actuator – your all-in-one solution for robotic joints. This innovative servomotor integrates dual absolute encoders, a controller, strain wave gear (SWG), and a servo motor within a single housing. The eRob series features a DC servomotor with a brushless AC core, providing optimal performance.

Enjoy peace of mind with Faradyi’s 1-YEAR WARRANTY and dedicated online support team, ready to assist you. Access detailed video instructions and technical documentation for seamless integration. With an average lead time of 2-4 weeks, Faradyi ensures timely delivery.

Pioneering quality, Faradyi holds the first international ISO9001 certificate among domestic counterparts, alongside CE certification and RoHS compliance. Our rotary actuators meet the Electromagnetic Compatibility Directive 2014/30/EU, ensuring reliability and compliance with international standards.

Servomotor1set

Lithium battery (Optional)1pcs

Key Information Manual1pcs

Packing List1pcs

Disposable gloves1pair

Final Quality Control Report1pcs

Certificate1pcs

| Model | Faradyi142I | ||||

| Strain wave gear – ratio | 32-50 | 32-80 | 32-100 | 32-120 | 32-160 |

| Peak torque for start and stop(Nm) | 281 | 395 | 433 | 459 | 484 |

| Permissible max.value at average load torque ( Nm ) |

140 | 217 | 281 | 281 | 281 |

| Rated torque ( Nm ) | 99 | 153 | 178 | 178 | 178 |

| Permissible maximum momentary torque ( Nm ) | 497 | 738 | 841 | 892 | 892 |

| Max . output rotational speed ( RPM ) | 40 | 25 | 20 | 16.7 | 12.5 |

| Motor power ( W ) | 1000 | ||||

| Strain wave gear output inertia ( g – mm² ) | 2589596 | ||||

| Strain wave gear output mass ( KG ) | 1.21 | ||||

| Outer diameter * length | 142*133.9mm | ||||

| Strain wave gear input inertia ( g – mm² ) | 1244894 | ||||

| Strain wave gear input mass ( KG ) | 1.33 | ||||

| Weight ( KG ) | 6.49 | ||||

| Common parameters | Supply voltage: 48V(±10%), ID: 18mm, IP grating:IP54*, Brake model: friction brake | ||||

| Optional device | Communication type: EtherCAT / CANopen/Modbus, Output encoder resolution: 19Bit. Repeatability/Accuracy: ±7/±15 arc seconds or ±10/±25 arc second. | ||||

| EtherCAT version rotary actuator | Optional interface: RS485, Pulse/DIR, I/O, ±10V Analog and STO. | ||||

| CANopen version rotary actuator | Optional interface: RS485, Pulse/DIR, I/O, ±10V Analog and STO. | ||||

1. Use tolerance: pay attention to the use range of voltage and current, and use the motor under the conditions specified in this standard, otherwise the life of the motor will be reduced.

2. Handling the motor: handle it with care, and use the motor casing as much as possible.

3. Motor wiring: the red lead wire is connected to the positive pole, and the black lead wire is connected to the negative pole. If the connection is reversed, the motor will rotate in the opposite direction.

4. Overload: Use it within the specified load range as much as possible. It is strictly forbidden to run the motor in a stalled state or close to the stalled state for a long time, otherwise the motor will burn out.

5. Motor storage:Storage temperature: 0C-40°C, storage humidity: 15%-90% RH

Avoid placing it in an environment with high temperature, high humidity and corrosive gas.

6. Motor operating temperature: 0°C-70C

1. When you use the motor, there must be no binding objects, such as adhesive, do not flow into the bearing through the rotating shaft, which will hinder the operation of the motor.

2. The rotation of the shaft may have the opposite effect on the life of the motor. In order to prolong the life, please check whether your load is in accordance with the regulations. Do not overload or hang items that hinder the rotation of the shaft.

3. Manufactured into an eccentric heavy radiation load, harmful to the life of the motor.

4. Do not store it in high temperature or extreme humidity, and do not place it in corrosive gas, which will reduce the effect of the motor

5. Do not run the motor in the surrounding high temperature and humidity.

6. When soldering on the positive and negative motor terminals of the power supply, the temperature of the soldering iron is 340C40C, and the heating time is within 3 seconds. Do not deform the plastic. Let the solder point flow into the motor or break the end of the wire during work, which will make the motor function decline.

7. Do not let the motor shaft get stuck. When the power is supplied, the motor will overheat in a short time and burn its accessories.

8. Supply the specified power and make sure it is within the range of measurable requirements.

9. When installing pulleys or gears, do not increase the weight abnormally when pressing them in.

10. When installing the motor, if the screw is too long, it will cause contact between the motor itself and the

rotor, which will affect the characteristics.

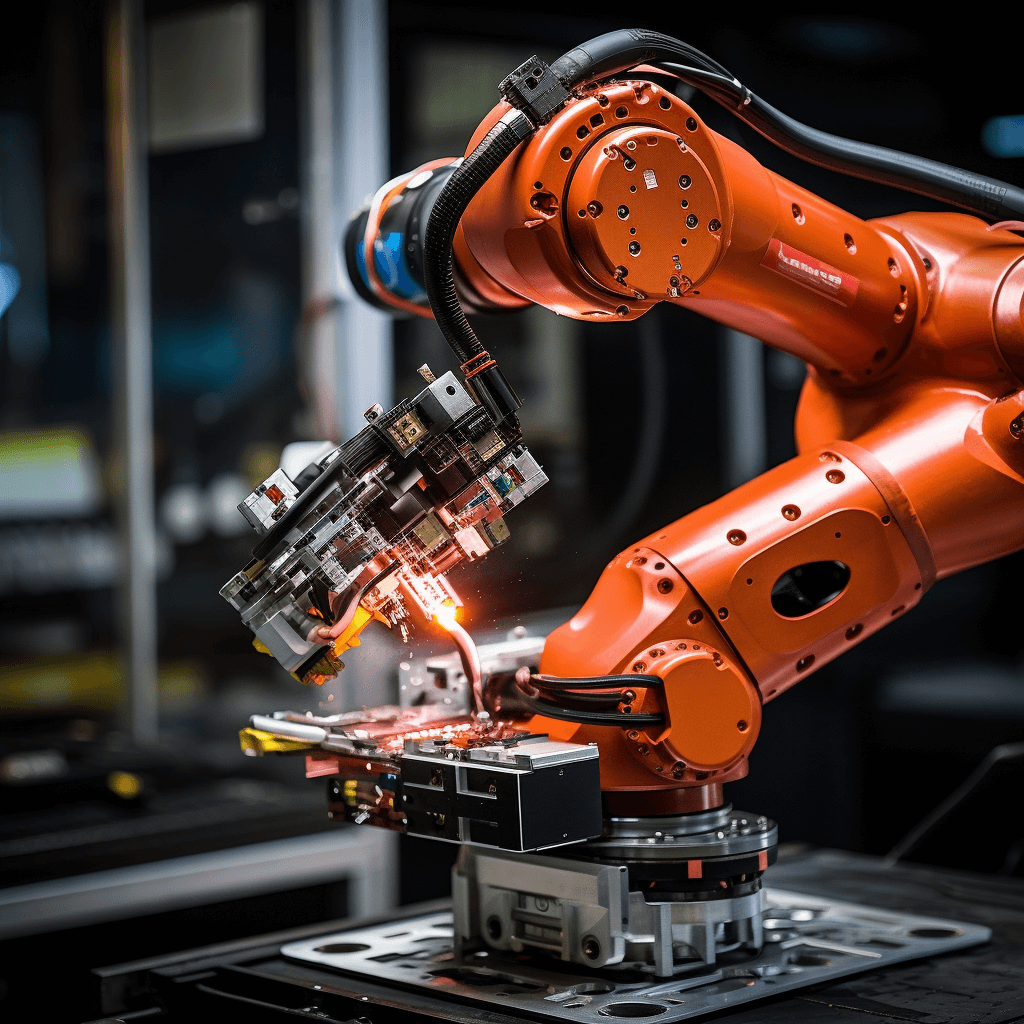

With EtherCAT, CANopen, Modbus communication protocols.

Position,Speed, Current loop PID adjustable in real-time.

Built-in ± 10V analog input.

Pulse and direction, I/O, RS485,

External encoder and STO interface,

All in the space of DxL=70x67mm

19bit absolute multiturn encoder for output shaft.

Repeatability up to ±7 arc seconds.

Absolute accuracy up to ±15 * arc seconds.

Always have real absolute position and multi-turn counter when power-off.

Brake smooth and stable.

No gap; No backlash.

No need to move when power-on.

No wear and tear.

Can be used as Emergency Stop.

We strive to provide exceptional products and service. If you are satisfied with your experience, we would greatly appreciate you taking a moment to leave us a review

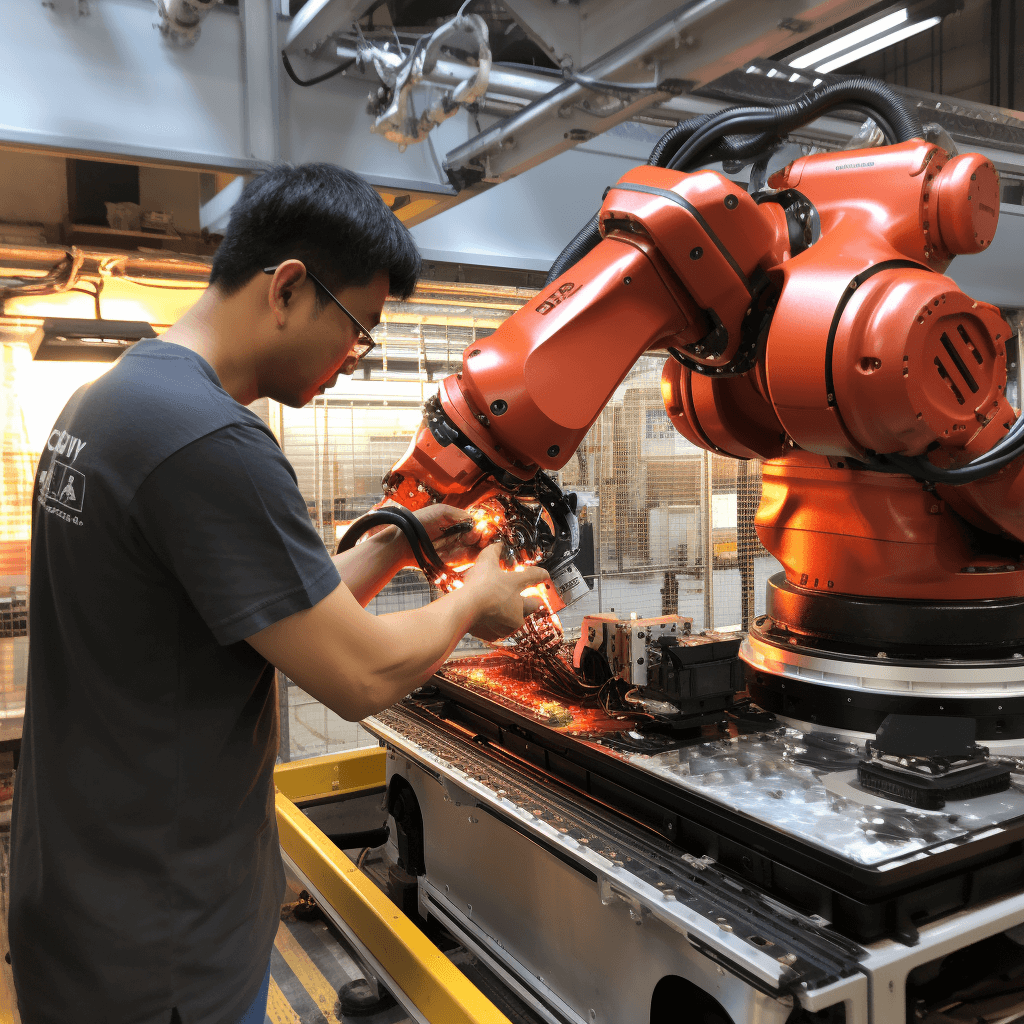

Faradyi manufactures high-quality brushless motors for aviation, robotics, medical, auto, machinery, new energy, and infrastructure industries globally.

Faradyi Motor Has Been Deeply Involved In The Motor Industry For Decades, Specializing In The Production Of Various Robots And Brushless Motors.Update more new news in real time~