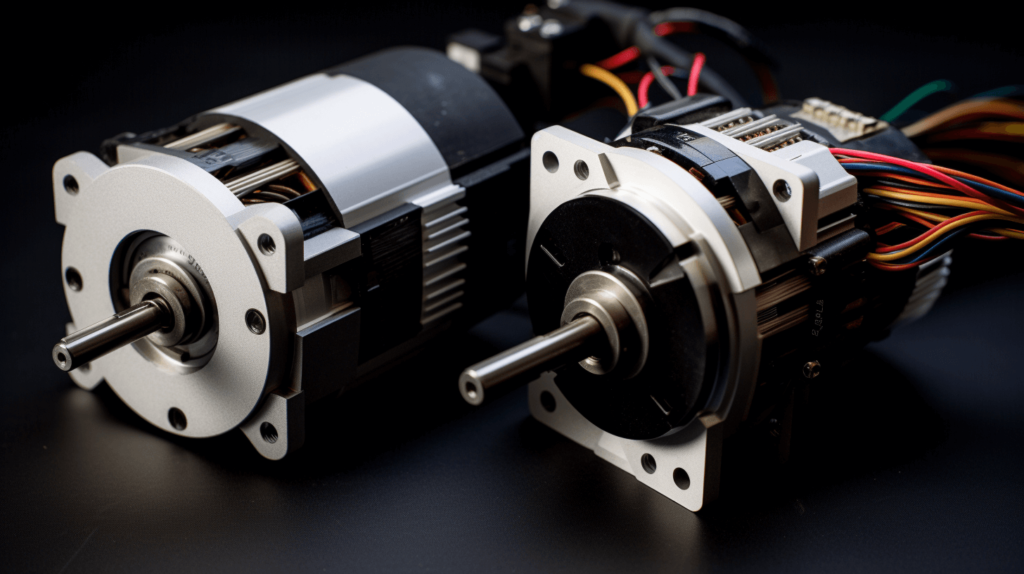

Stepper motors are brushless, synchronous electric motors that divide a full rotation into a large number of steps. They offer precise positioning and control without any feedback mechanism, making them ideal for many applications. This complete guide covers everything you need to know about stepper motors.

What is a Stepper Motor?

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. The motor’s position can be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is carefully sized to the application.

How Stepper Motors Work

Stepper motors operate on the principle of electromagnetism. The basic construction consists of a rotor made of permanent magnet and a stator with electromagnets. When current flows through the coils in the stator, it generates a magnetic field that interacts with the field of the permanent magnet rotor to cause rotation.

By precisely controlling the sequence and timing of the current in the coils, the motor can be made to move in discrete rotational steps. Common step angles are 15°, 7.5°, 5°, 2.5°, and 1.8°. The smaller the step angle, the higher the resolution and positional accuracy.

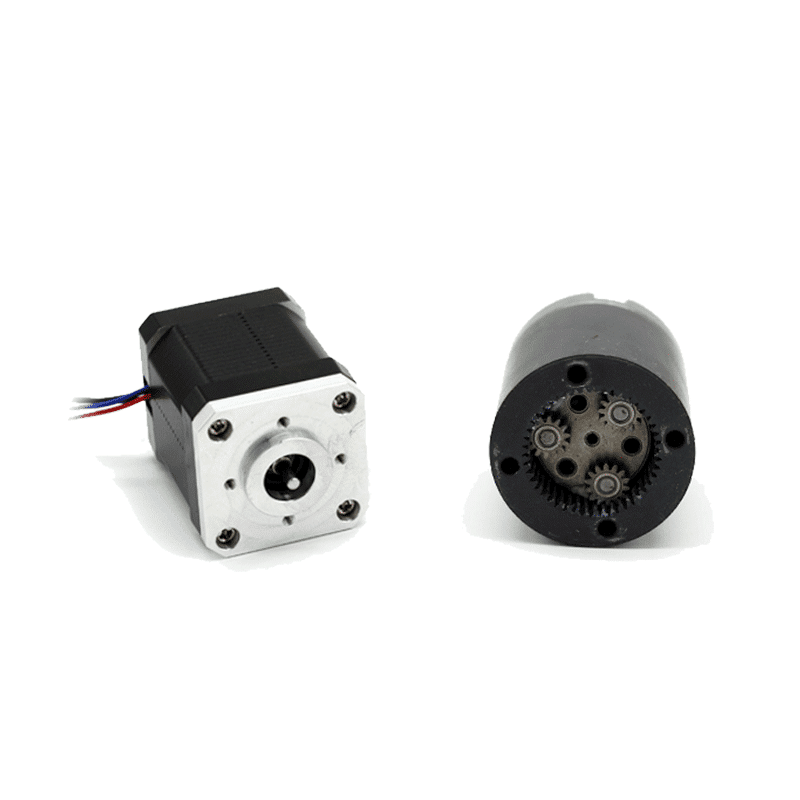

Types of Stepper Motors

There are three main types of stepper motors:

- Variable Reluctance – Has a plain iron rotor and stator poles that are energized to attract the rotor.

- Permanent Magnet – Has permanent magnets on the rotor and operate based on attraction/repulsion between rotor and stator magnets.

- Hybrid – Combines both VR and PM principles for high power in a small form factor.

The hybrid bipolar stepper motor is most common, providing good low-speed torque and faster motion control.

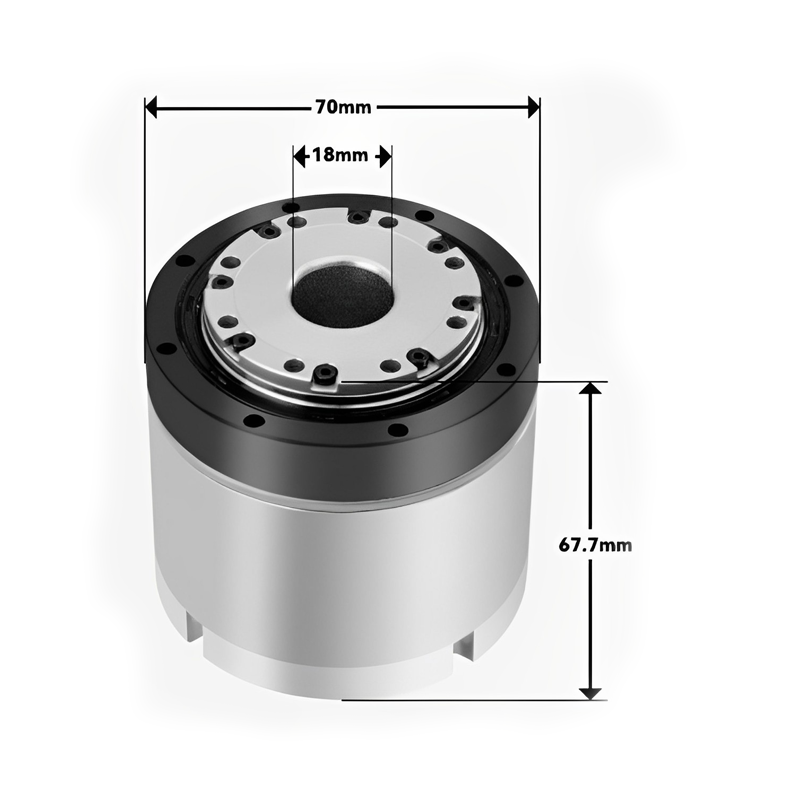

How to Choose a Stepper Motor

Key factors to consider when selecting a stepper motor:

- Torque and speed requirements – The motor must be properly sized and matched to the load inertia.

- Step angle – Smaller step angles provide better resolution and accuracy.

- Bipolar or unipolar – Bipolar motors provide more torque but require a more complex driver.

- Driver type – Must provide adequate current and match the interface type.

- Holding torque – Must be greater than load torque to prevent slippage.

- ** Voltage and current** – Must match motor ratings.

Controlling a Stepper Motor

Stepper motors require dedicated drivers to energize the phases in sequence. Common driving modes:

- Wave drive – Only one coil is energized at a time.

- Full step – Two coils are energized at once to provide higher torque.

- Half step – Alternates between one and two coils energized.

- Microstepping – Sinusoidal excitation for increased resolution.

Microcontroller interfaces using digital I/O pins or specialized stepper controllers can control the motor position and speed by commanding the driver with the proper step and direction signals.

Stepper Motor vs Servo Motor

| Stepper Motor | Servo Motor |

|---|---|

| Precise positioning and control | Higher speed operation |

| Open loop | Closed loop with encoder feedback |

| Low cost | More expensive |

| High holding torque | High dynamic torque |

Advantages of Stepper Motors

- Precise digital control of position, speed and acceleration

- Repeatability and accuracy

- High torque at low speeds

- Low maintenance

- Long service life

Applications of Stepper Motors

Stepper motors are used in:

- Automation equipment

- Semiconductor manufacturing

- Medical devices

- Robotics

- Packaging machinery

- Computer peripherals

- Printers/scanners

- Security systems

With their unique advantages, stepper motors will continue to be an integral component of motion control systems requiring precision position, speed, and timing.CopyRetry