There is a basic difference between vector control and sine wave control of brushless motors, which is the way they control the current of brushless motors. As the speed of the brushless motor increases, the bandwidth of the P-I controller for sine wave control will reach the limit, resulting in control failure. In contrast, vector control achieves precise control of the stator coil current by directly controlling the vector current components in the parallel and perpendicular directions of the rotor magnetic field. Under vector control, the current control no longer changes with time, but becomes static DC control, thus eliminating the limitations of frequency response and phase drift. Therefore, the current quality under vector control mode has nothing to do with the motor speed.

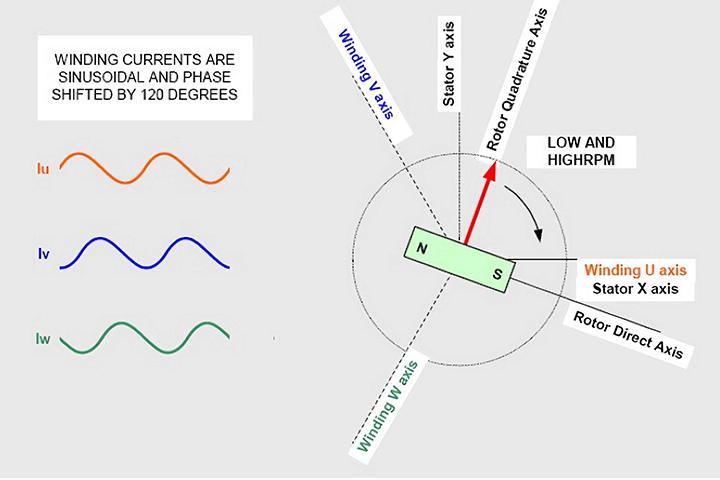

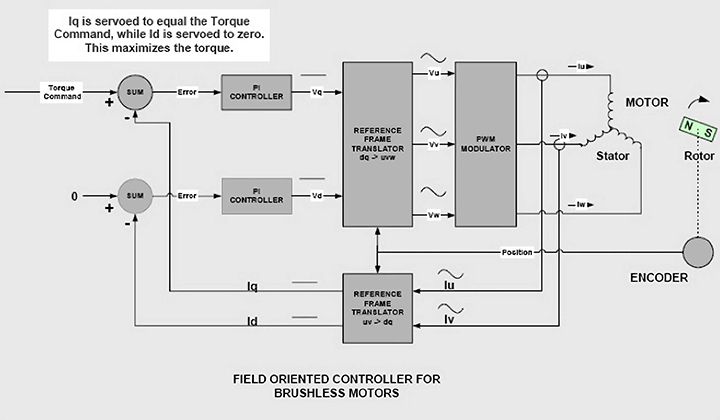

In the case of vector control, we mainly control the components of the brushless motor current and voltage in the parallel and vertical directions of the rotor magnetic field. This means that we need to mathematically calculate the current measured from the brushless motor to convert it from the three-phase static structure of the stator to the dynamic d-q structure of the rotor (parallel and perpendicular to the rotor magnetic field direction). Similarly, the control voltage at the brushless motor end also needs to be mathematically calculated to convert it from the d-q structure of the rotor to the three-phase static structure of the stator, and then input to the PWM part for modulation. These conversions require high-speed mathematical processing capabilities, so DSP and high-performance processors become the core of vector control.

Although this conversion can be completed in only one calculation, for the convenience of description, we divide it into two steps. First, the motor current changes from the physical three-phase structure of the stator with a phase difference of 120 degrees to a stable dynamic right-angle orthogonal d-q structure, and then converts this dynamic structure of the stator into the three-phase static structure of the rotor. To guarantee valid results, these calculations must be completed within one sampling period of the P-I controller. The above conversion is the opposite of the operation of converting the voltage signal required by the P-I controller from the d-q structure to the three-phase structure of the stator coil.

Once the brushless motor current is converted into a d-q structure, control becomes very simple. We need two P-I controllers: one to control the current parallel to the rotor magnetic field and one to control the current perpendicular to the rotor magnetic field. Since the control signal of the parallel current is zero, the parallel current component of the brushless motor also becomes zero, converting all the current vectors of the brushless motor into vertical current. This maximizes the efficiency of brushless motors because only vertical current can produce effective torque. Another P-I controller is mainly used to control the vertical current to obtain the required torque consistent with the input signal. This ensures that the vertical current is controlled as required to obtain the required torque.

The output signals of the two P-I controllers represent the voltage vector of the rotor. These static voltage vectors undergo a series of reference coordinate conversions to obtain the voltage control signals required for the output bridge. They are first converted from the dynamic d-q reference structure of the rotor to the static x-y structure of the stator. The voltage signal is then converted into physical structures spaced 120 degrees apart from each other, and finally input into the U, V and W three-phase coils of the brushless motor. These three voltage signals need to be PWM modulated before being input to the brushless motor coil.

The work of converting the time-varying sinusoidal current and voltage signals in the brushless motor coil into a d-q structure DC signal is the conversion of the reference coordinates.

The essential difference between sine wave commutation and vector control lies in the way coordinate conversion and current control are handled. In the sine wave commutation method, we first perform commutation, and then obtain the required sine wave current through P-I control. Therefore, the P-I control of the system mainly processes the time-varying sinusoidal signals of brushless motor current and voltage, and the performance of the brushless motor will be limited by the controller bandwidth and phase drift. In vector control, the current signal is first controlled by P-I, and then undergoes high-speed commutation processing. Therefore, the P-I controller does not need to process time-varying current and voltage signals, and the system will not be affected by the bandwidth and phase drift of the P-I controller.

Therefore, Why Is Vector Control Superior?

Vector control makes the motor behave equally smoothly at low speeds as at high speeds. In contrast, sinusoidal commutation enables smooth operation at low speeds but results in a significant reduction in efficiency at high speeds. The trapezoidal wave commutation behaves normally when the motor is running at high speed, but it will cause torque fluctuations at low speed. Therefore, vector control is considered the best control method for brushless motors.