6 criteria to choose the right motor for a jointed arm robot

Selecting the right motors for a collaborative robot dedicated to research and education is indeed crucial for achieving precise and efficient movements. Here are some key criteria to consider when choosing motors for such a robot

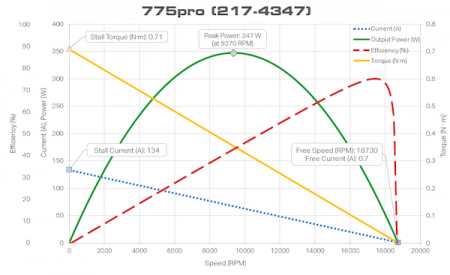

1. Power and Torque

- Determine the maximum weight the robot needs to handle. Choose a motor that can handle at least this payload capacity with some margin for safety and future expansion.

- The higher the gear ratio of the reducer, the higher the maximum acceleration of the motor.

2. Maximum Acceleration

- Torque is the rotational force provided by the motor. Higher torque motors can handle heavier loads and offer better performance in challenging tasks. Consider the torque requirements based on the weight and type of objects the robot will interact with.

3. Precision and Accuracy

- For research and educational purposes, precise and accurate movements are essential. Motors with high precision and low backlash will ensure that the robot can repeat tasks reliably.

4.Power Efficiency

- Motors that are power-efficient will help extend the robot’s battery life, reducing the frequency of recharges during operation.

5.Safety Features

- Collaborative robots work in close proximity to humans, so safety is critical. Look for motors with built-in safety features, such as current limiting and thermal protection, to prevent overheating and potential hazards.

6.Speed

- The speed of the motors will affect the robot’s motion capabilities. Depending on the application, you may need to balance between high-speed movements for quick actions or slower speeds for more precise tasks.

- While industrial robotic arms often require high speed capabilities, those designed for education typically have lower speed requirements. However, a motor with high speed capability can still be beneficial in certain applications, such as when the robot needs to perform fast movements or when a higher operating frequency is required according to the robotic use cases.

- The speed of an educational arm robot depends on its intended use, but generally, a motoreducer with a speed range of 10-100 RPM is sufficient for most applications. The motor should also be capable of maintaining consistent speed throughout its range of motion, to ensure accurate and precise movements.

7.Availability and Support

- Check the availability of spare parts and technical support for the chosen motors. Having access to spare parts and reliable support can significantly reduce downtime in case of any issues.