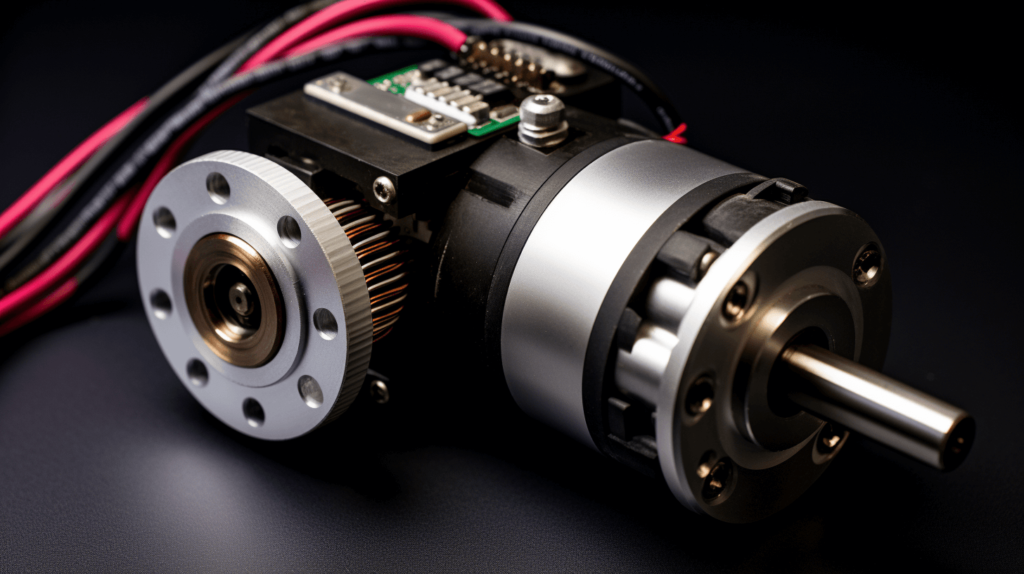

Servo motors are critical components in many industrial machines and robots. However, like any component, servo motors can malfunction or fail over time. Knowing how to properly test and repair servo motors is key to ensuring continued performance and minimizing downtime.

What are Servo Motors and Why Do They Fail?

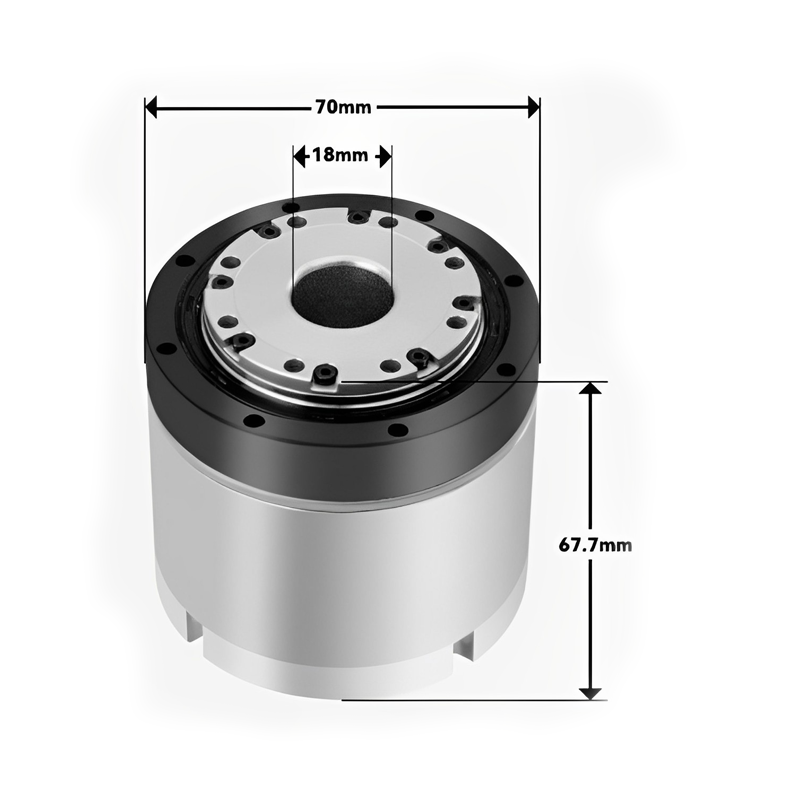

Servo motors are brushless DC electric motors combined with position sensors and control circuitry. This allows for precise speed and position control, which is vital in applications like robotics, CNC machines, packaging equipment, and more.

Common reasons for servo motor failure include:

- Bearing wear

- Debris/contamination

- Issues with the encoder (position sensor)

- Short circuits in the windings

Without proper testing, it can be difficult to pinpoint the exact cause of the malfunction.

How to Test a Servo Motor for Problems

To accurately diagnose servo motor issues, specialized testing is required. Here are some key ways to test a servo motor:

1. Check Winding Resistance

Using a multimeter, you can measure the resistance between the motor phase wires. Resistance should be balanced; any significant deviation could indicate a short circuit or open winding.

2. Test the Encoder

Encoders can fail due to issues with the sensing disc or electronics. Dedicated encoder testers can check encoder operation and alignment.

3. Run Testing

Run testing tools allow you to simulate operating the servo motor without the need for the original drive. This verifies basic motor operation and can detect problems like high vibration or noise.

Repairing and Reassembling Servos

Many issues like bearing wear, debris contamination, or shorted windings can be repaired. The key is proper disassembly, inspection, replacement of damaged components, and reassembly.

The encoder must be realigned after disassembly to ensure proper operation. Dedicated alignment tools simplify this process by automatically calculating alignment angle based on the specific motor.

Proper testing, repair procedures, and alignment tools allow efficient servo motor refurbishment, reducing costs and downtime.

The Benefits of Faradyi Servo Motor Service

Servos are high-value components, so repairing and extending service life offers big advantages:

- Minimizes costs compared to replacement

- Reduces downtime from long lead times for new servos

- Avoids e-waste from discarding working servos

With the right knowledge and tools, even complex modern brushless servo motors can be tested, repaired, and returned to service quickly. Investing in these capabilities in-house provides flexibility and ensures you can keep your machines running at peak performance.