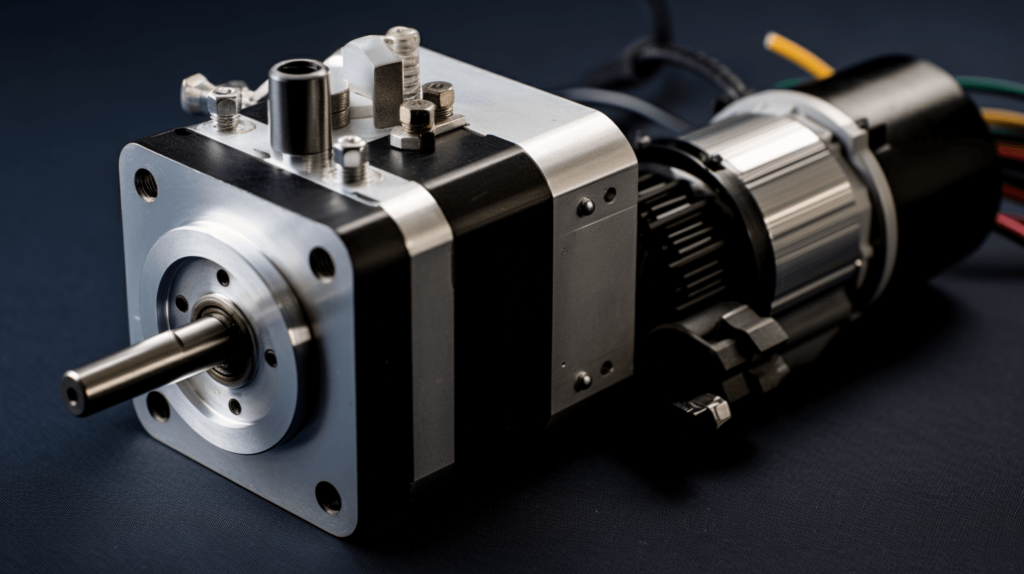

Connecting stepper motors to a CNC controller like the Buildbotics system requires identifying the right wires and making the proper connections. This guide will show you how to connect 4-wire, 6-wire, and 8-wire stepper motors for CNC applications.

Introduction

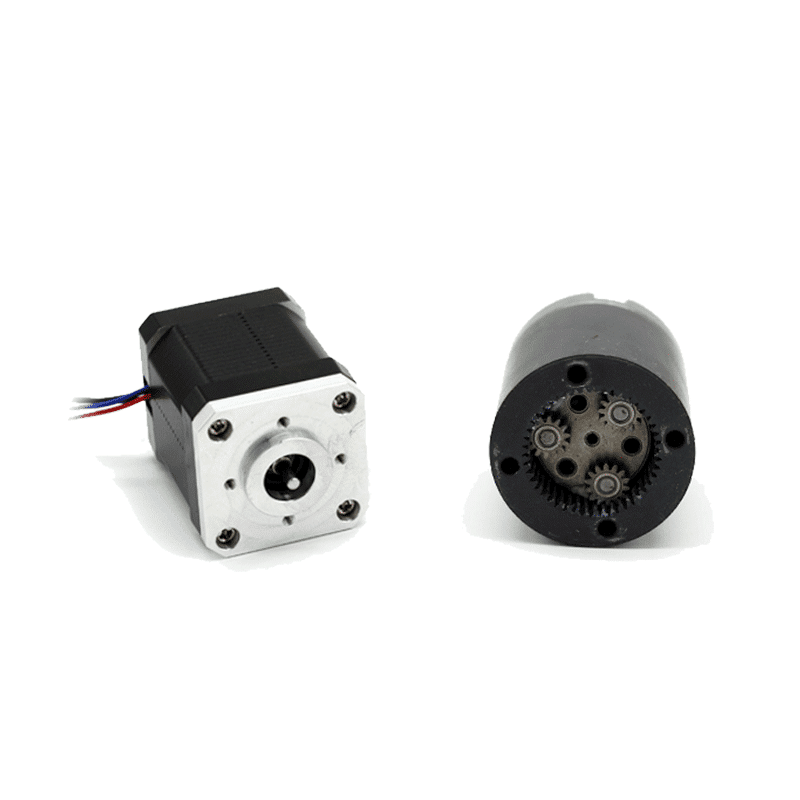

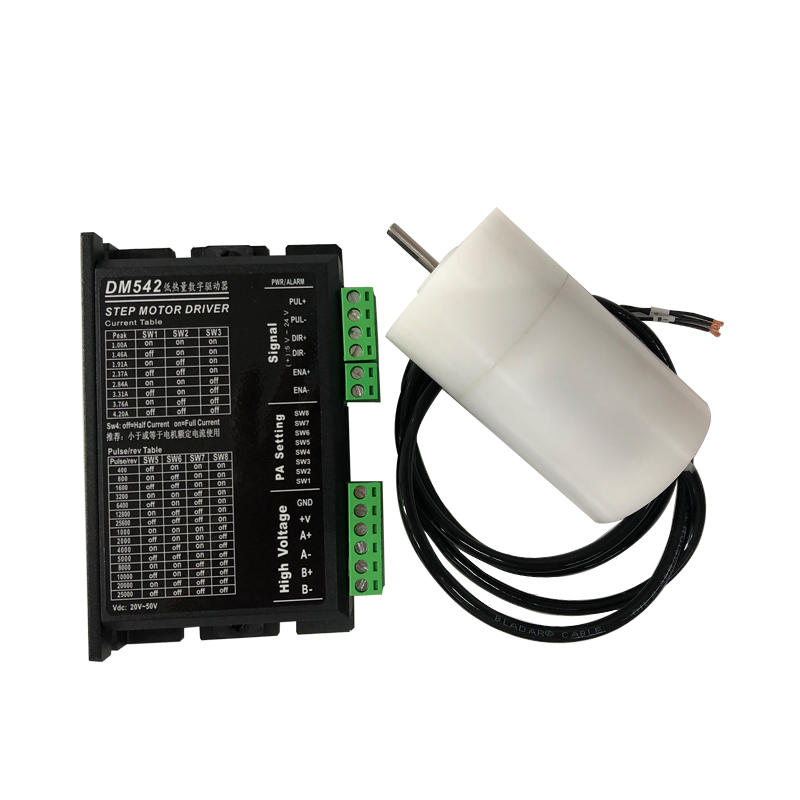

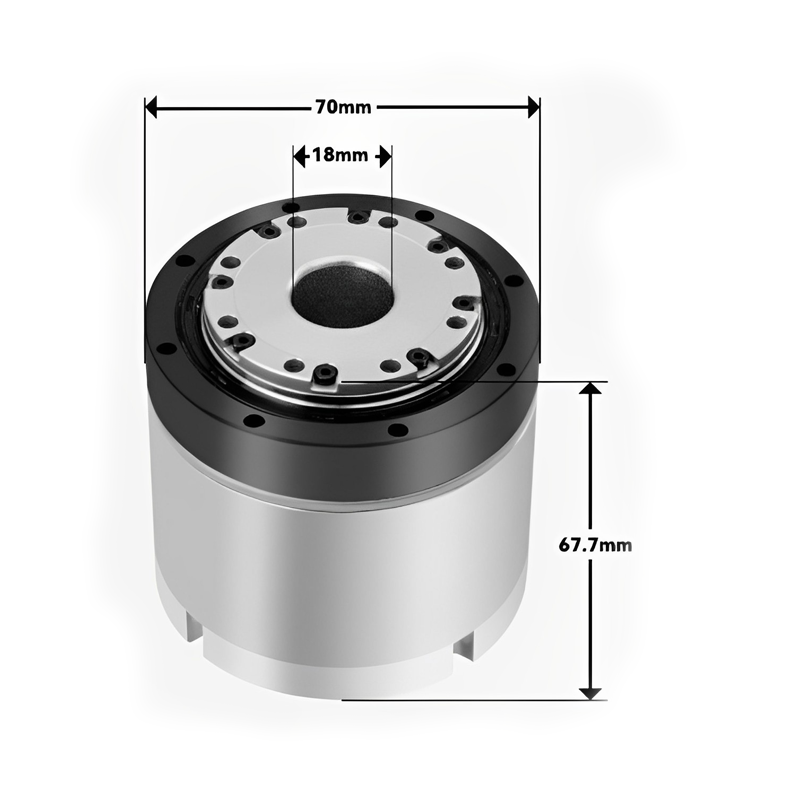

Stepper motors come in a variety of configurations, with 4, 5, 6 or 8 wires coming out of the motor. The Buildbotics CNC controller provides 4 bipolar stepper motor drivers, so the motors must be wired in a bipolar configuration.

The controller has 4 motor outputs labeled X, Y, Z and A, each with 4 pins:

- B+ (yellow wire)

- B- (purple wire)

- A+ (red wire)

- A- (black wire)

B+ and B- must connect to one motor coil, while A+ and A- connect to the other coil.

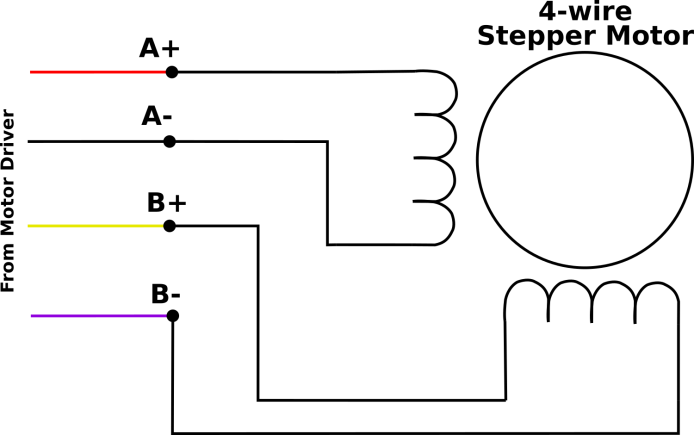

Connecting 4-Wire Motors

4-wire motors have two coil pairs inside. To connect:

- Identify the coil pairs by checking the wiring diagram, measuring resistance with a multimeter, or shorting pairs to feel which are harder to turn.

- Arbitrarily assign one pair to A and the other to B. Assign one wire in each pair + and the other -.

- Connect B+ to yellow, B- to purple, A+ to red, and A- to black.

- If the motor turns the wrong way, swap the + and – of one coil pair.

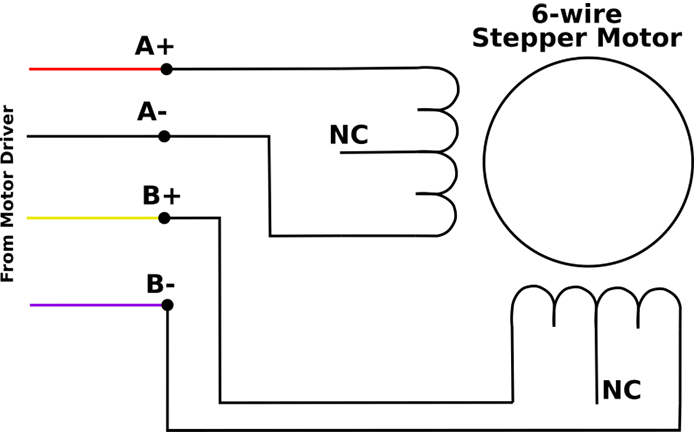

Connecting 6-Wire Motors

6-wire motors have two center-tapped coils. To connect in a bipolar series configuration:

- Identify the coils and centers either from documentation or with a multimeter.

- Assign one coil to A and the other to B arbitrarily.

- Pick coil ends as + and -.

- Connect coil ends to driver, leaving centers disconnected.

- Swap one coil pair if it turns backwards.

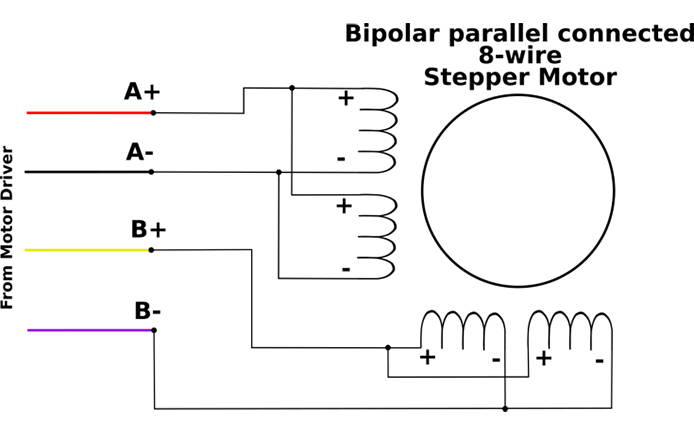

Connecting 8-Wire Motors

8-wire motors can be wired in series or parallel.

For a series connection:

- Follow the 6-wire steps above using two center-tapped coils.

For a parallel connection:

- Follow the 6-wire steps but connect both ends of each coil.

- Use series wiring if the current exceeds the driver capability.

Conclusion

Properly identifying motor coils and polarity is key to wiring stepper motors for CNC applications. Following the steps above will get your motors running properly with the Buildbotics controller. Check the manufacturer’s datasheet whenever possible.