- (+086) 18923470557

- [email protected]

- 7F, No.53 Fofu Road, Dalang Town, Dongguan City, Guangdong, CN,523770

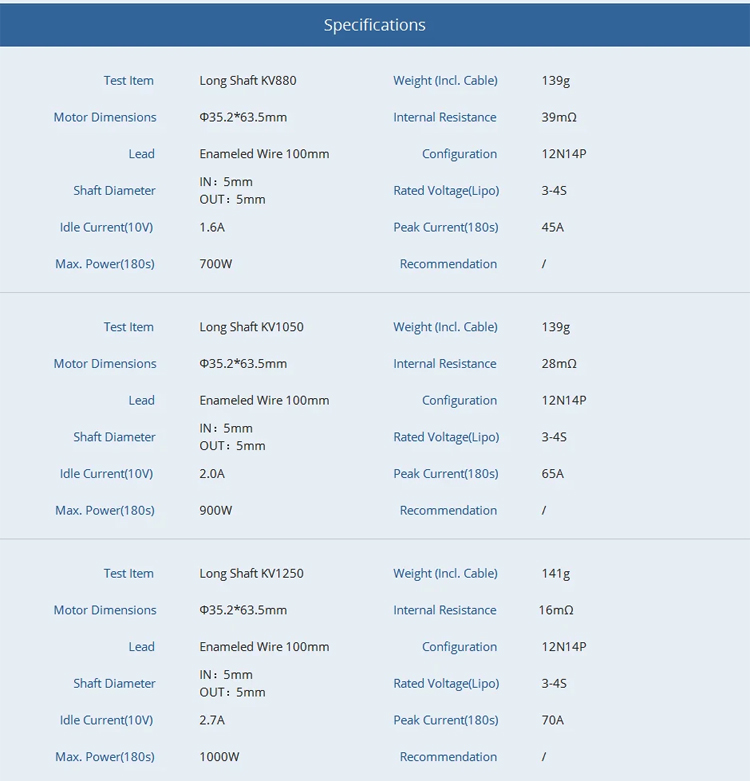

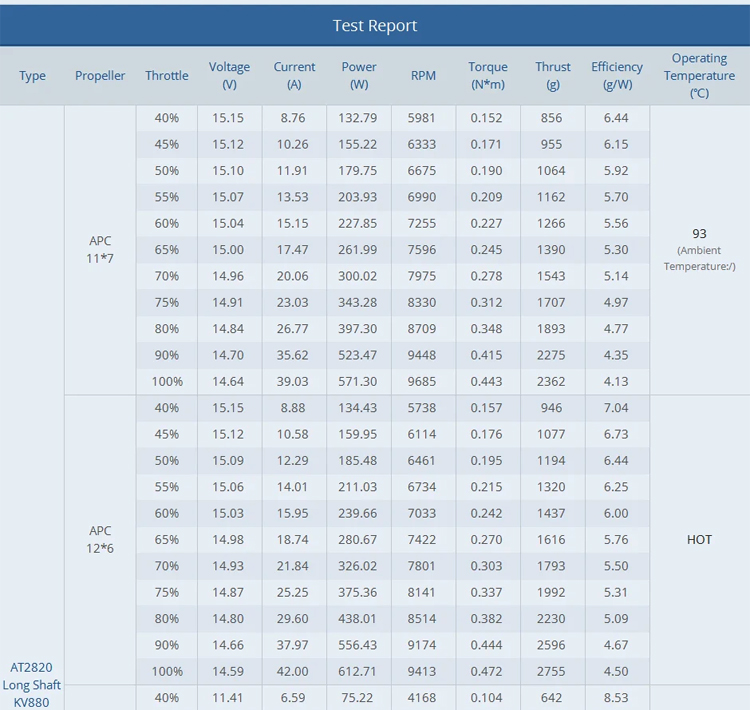

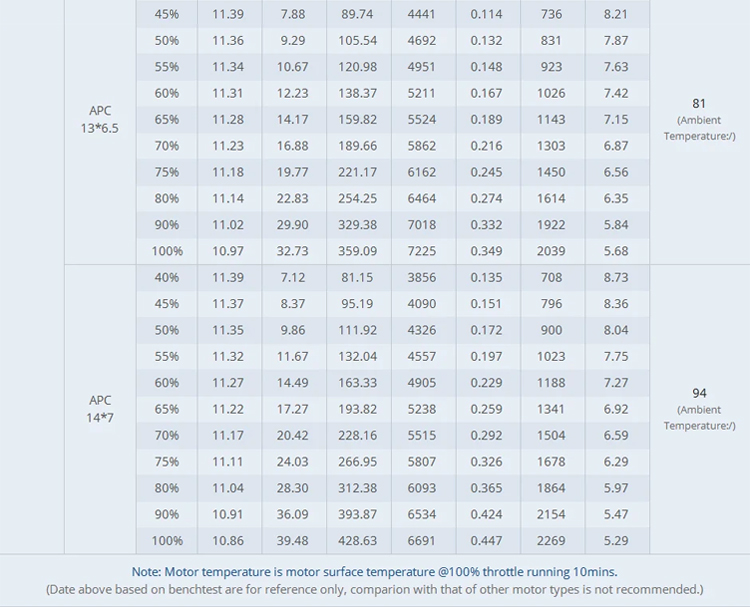

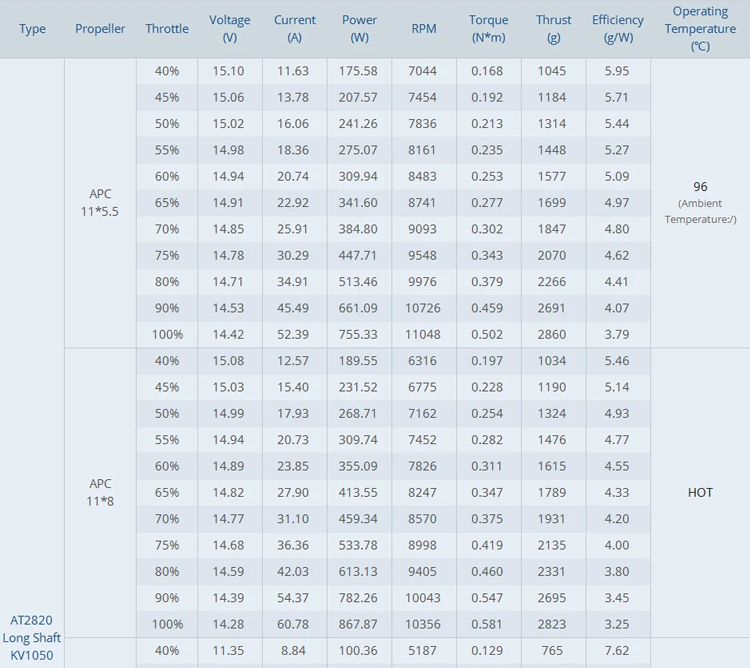

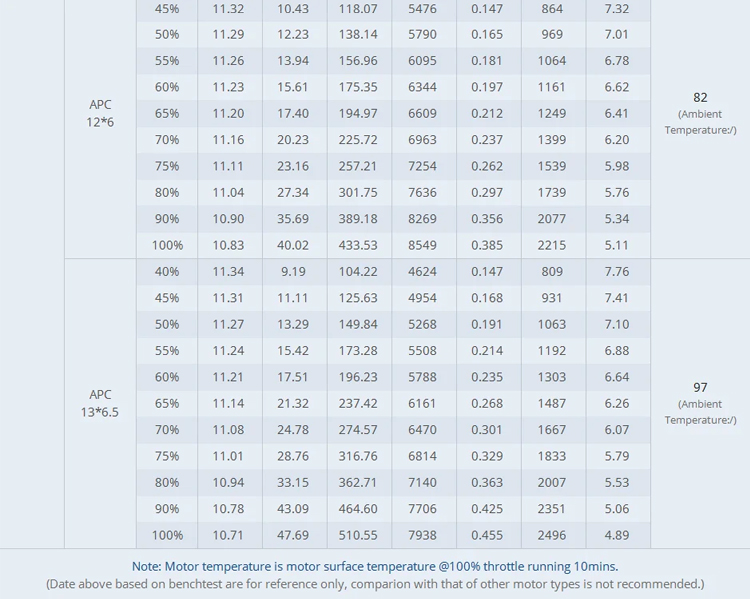

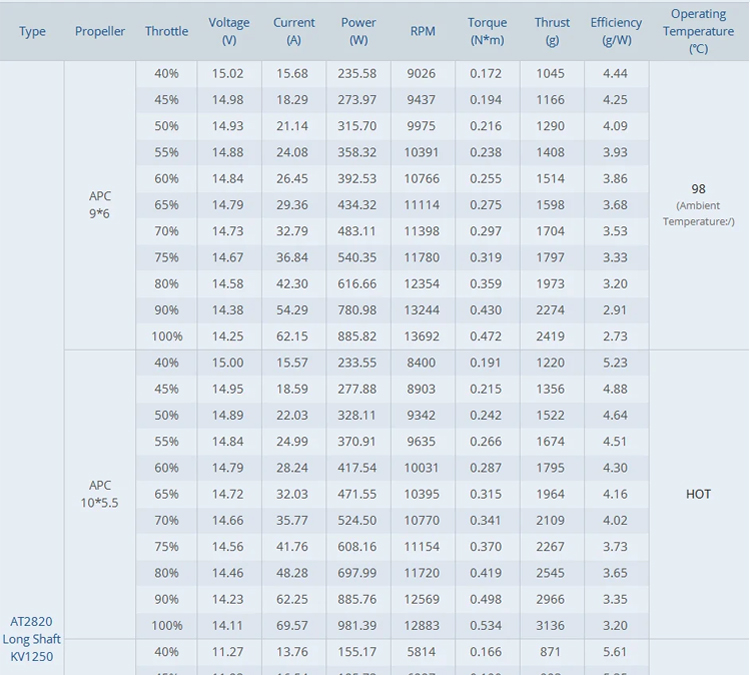

Elevate your UAV FPV drone experience with the cutting-edge BLDC 45A 15V 1000KV Brushless Motor. Specifically designed for fixed-wing powered aircraft, the AT2820 Long Axis offers three powerful KV options: 880, 1050, and 1250, providing versatility for various applications.

High-Performance Innovation: Experience high performance and temperature resistance with the uniquely designed curved magnet, delivering large torque for optimal propulsion. The motor’s maximum pulling force exceeds an impressive 3.1KG, ensuring superior efficiency and power.

Enhanced Design for Maximum Strength: The AT2820 KV1050 model takes it a step further with a reinforced fitness board, allowing for unrestricted performance. The semi-box structure, created by side air outlets and internal heat dissipation blades, not only boosts strength but also optimizes heat dissipation, ensuring peak performance even under demanding conditions.

Safety First, Always: The anti-off design guarantees safety with a straight-shaped steel shaft and a double safety mechanism featuring circlip lock shaft and lock shaft ring lock shaft. This ensures the motor’s reliability and safety even at high rotation speeds and power levels.

Crafted for Excellence: Selected raw materials and meticulous workmanship define the AT2820 series. Every detail is carefully considered, resulting in a motor that stands out for its durability, precision, and overall excellence.

Bearing the Load: Larger motors (28 series and above) feature a 3-bearing package, providing unparalleled stability, efficiency, and strength under heavy loads. This innovative bearing design ensures a safer and more stable operation, making it the ideal choice for high-performance drone applications.

Upgrade your drone’s propulsion system with the AT2820 KV1050 Brushless Motor – where power meets precision, and innovation takes flight.

| Factory | Faradyi Motors |

|---|---|

| Model | AT2820 |

| Usage | UAS UAV FPV RPAS Drone Motor |

| Protect Feature | Explosion-proof |

| Rated Voltage | 24DC |

| Rated Power | 1100W-1300W |

| Rated Speed | 5900~11000rpm |

| Rated Current (A) | 1.6, 2.0, 2.7 |

| Rated Power (W) | 1000, 700, 900 |

| Frame Size (mm) | Φ35.2 * 63.5 |

| Rated Speed (rpm) | >8000rpm |

| Rated Voltage(V) | 15, 12 |

| Shaft Diameter(mm) | 5 |

Thanks for sharing it !

Proudct Information:

Description

Faradyi Motors Service

1. Use tolerance: pay attention to the use range of voltage and current, and use the motor under the conditions specified in this standard, otherwise the life of the motor will be reduced.

2. Handling the motor: handle it with care, and use the motor casing as much as possible.

3. Motor wiring: the red lead wire is connected to the positive pole, and the black lead wire is connected to the negative pole. If the connection is reversed, the motor will rotate in the opposite direction.

4. Overload: Use it within the specified load range as much as possible. It is strictly forbidden to run the motor in a stalled state or close to the stalled state for a long time, otherwise the motor will burn out.

5. Motor storage:Storage temperature: 0C-40°C, storage humidity: 15%-90% RH

Avoid placing it in an environment with high temperature, high humidity and corrosive gas.

6. Motor operating temperature: 0°C-70C

1. When you use the motor, there must be no binding objects, such as adhesive, do not flow into the bearing through the rotating shaft, which will hinder the operation of the motor.

2. The rotation of the shaft may have the opposite effect on the life of the motor. In order to prolong the life, please check whether your load is in accordance with the regulations. Do not overload or hang items that hinder the rotation of the shaft.

3. Manufactured into an eccentric heavy radiation load, harmful to the life of the motor.

4. Do not store it in high temperature or extreme humidity, and do not place it in corrosive gas, which will reduce the effect of the motor

5. Do not run the motor in the surrounding high temperature and humidity.

6. When soldering on the positive and negative motor terminals of the power supply, the temperature of the soldering iron is 340C40C, and the heating time is within 3 seconds. Do not deform the plastic. Let the solder point flow into the motor or break the end of the wire during work, which will make the motor function decline.

7. Do not let the motor shaft get stuck. When the power is supplied, the motor will overheat in a short time and burn its accessories.

8. Supply the specified power and make sure it is within the range of measurable requirements.

9. When installing pulleys or gears, do not increase the weight abnormally when pressing them in.

10. When installing the motor, if the screw is too long, it will cause contact between the motor itself and the

rotor, which will affect the characteristics.

Related Products

We strive to provide exceptional products and service. If you are satisfied with your experience, we would greatly appreciate you taking a moment to leave us a review

Faradyi manufactures high-quality brushless motors for aviation, robotics, medical, auto, machinery, new energy, and infrastructure industries globally.

Faradyi Motor Has Been Deeply Involved In The Motor Industry For Decades, Specializing In The Production Of Various Robots And Brushless Motors.Update more new news in real time~