A coreless motor, also known as a ironless or basket motor, is a unique type of direct current (DC) electric motor. Unlike conventional DC motors, coreless motors do not use an iron core in their rotor. This allows for some key advantages in performance.

How Coreless Motors Are Constructed

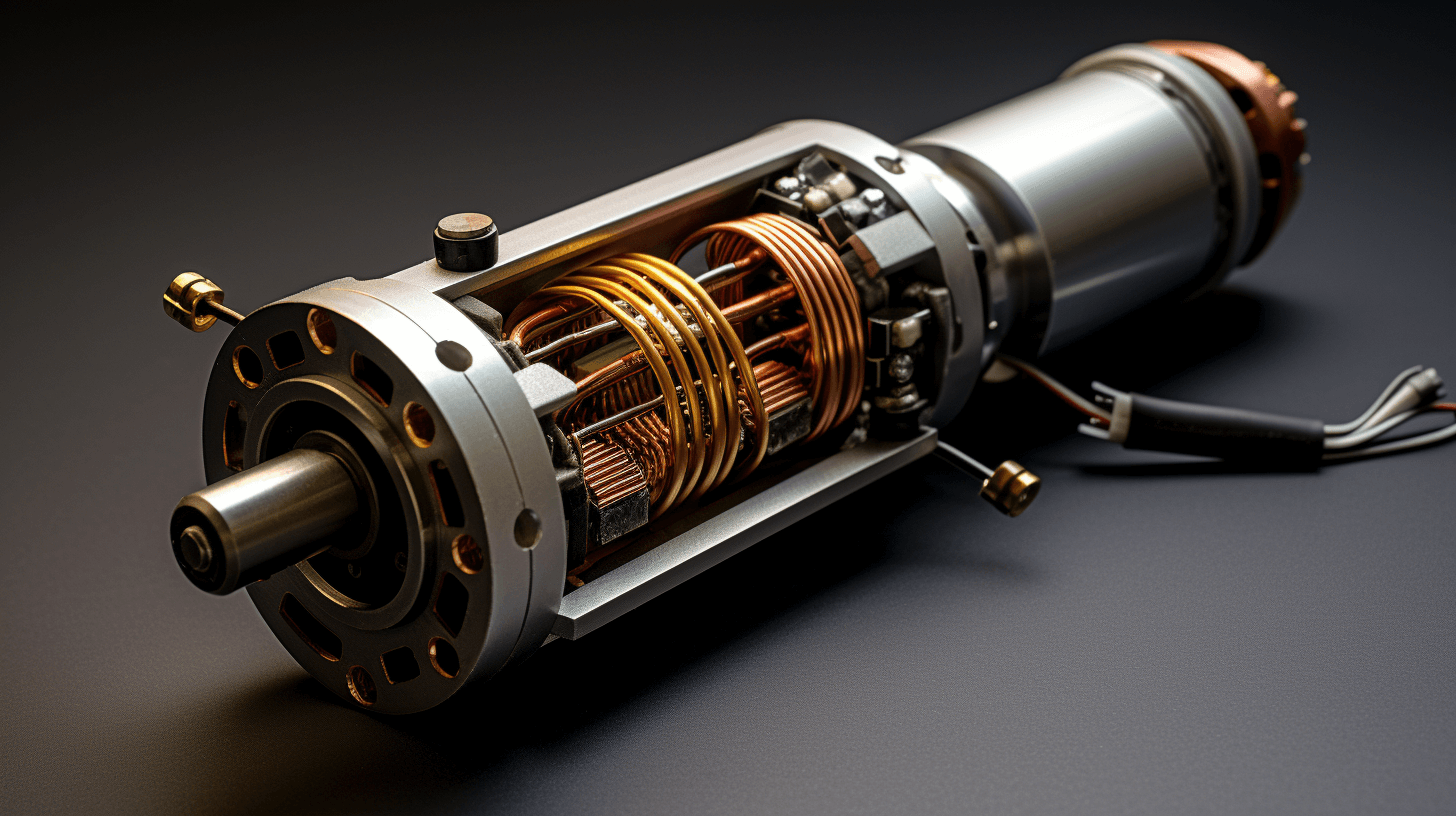

In a typical iron core DC motor, the rotor consists of an iron core with copper windings wrapped around it. The stator contains permanent magnets. When current flows through the rotor windings, it generates a magnetic field that interacts with the stator magnets, causing the rotor to spin.

In a coreless motor, the rotor is constructed without an iron core. Instead, the copper windings are wound in a special skewed pattern, like a basket or honeycomb. This winding pattern creates a hollow cylinder that is self-supporting, without the need for an iron core. The windings are often held together with epoxy.

The stator, containing permanent magnets, sits inside this rotor “basket”. When current flows through the rotor, the magnetic fields interact to produce torque.

Benefits of Eliminating the Iron Core

Removing the iron core provides several key benefits for coreless motors:

- Low inertia – The lack of iron greatly decreases the rotor’s mass and inertia. This allows for faster acceleration and deceleration.

- Efficiency – Coreless motors can achieve efficiencies over 85%, much higher than iron core motors. This results in less wasted energy and heat.

- Smooth torque – The iron core is a major cause of torque ripple or cogging in motors. A coreless motor operates very smoothly even at low speeds.

- Rapid response – The low inductance of a coreless motor gives it a very fast response time to changes in current and voltage.

- Low noise – Coreless motors produce much less audible noise compared to iron core motors.

Applications of Coreless Motors

The high acceleration, precision, and efficiency of coreless motors make them well-suited for applications like:

- Hobby RC vehicles

- Drones and quadcopters

- Robotics

- Precision positioning equipment

- Medical devices

- Automated production machinery

Overall, coreless motor technology enables high performance in a compact, lightweight package – ideal for applications where rapid motion and dynamic speed control are critical.

Get More Information About Coreless Motor.

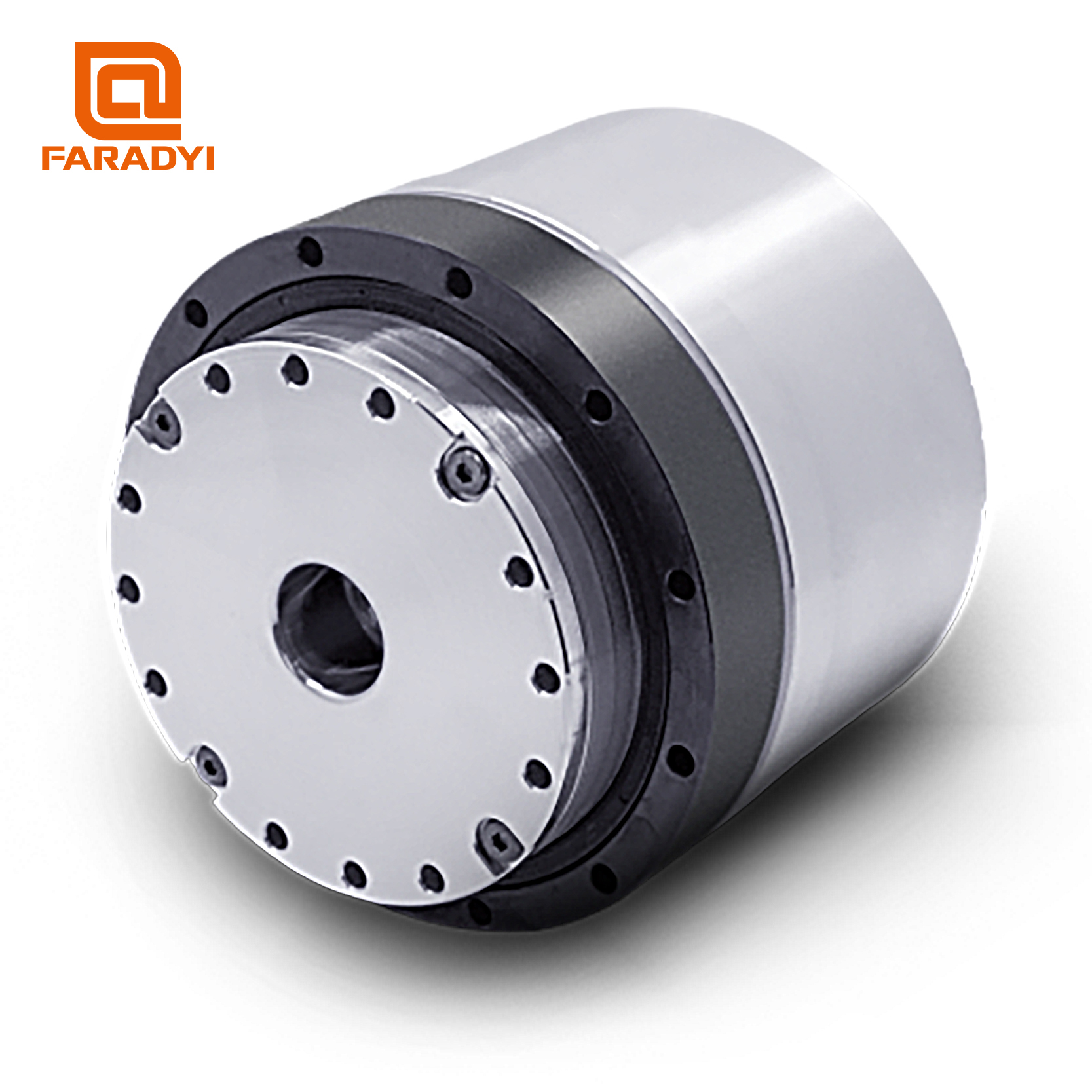

Faradyi Motor Has Been Deeply Involved In The Motor Industry For Decades, Specializing In The Production Of Various Robots And Coreless Motors Check out the Faradyi Coreless Collections and Asking our Engineer for help.