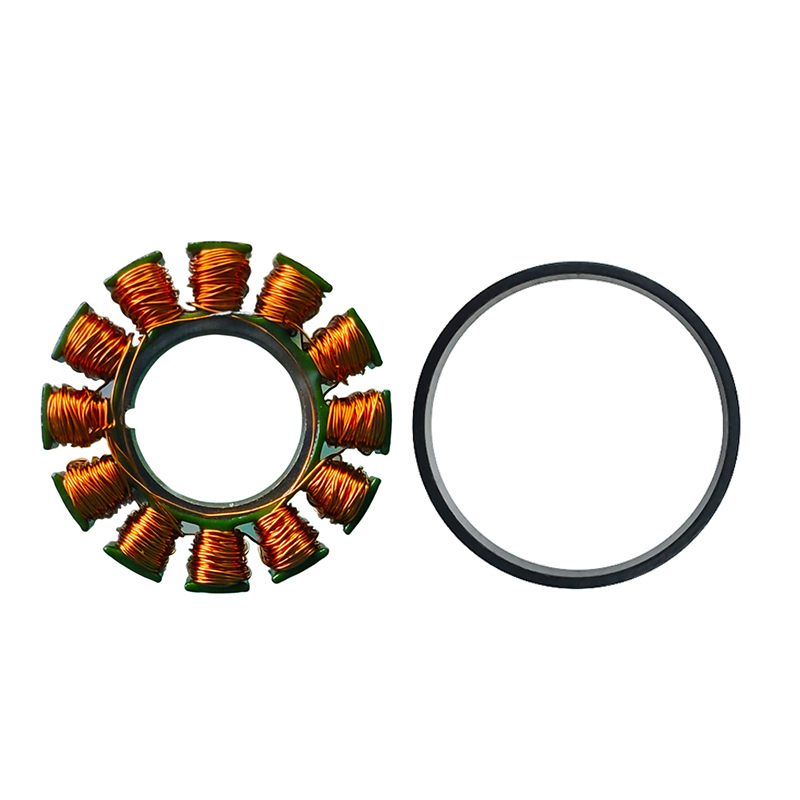

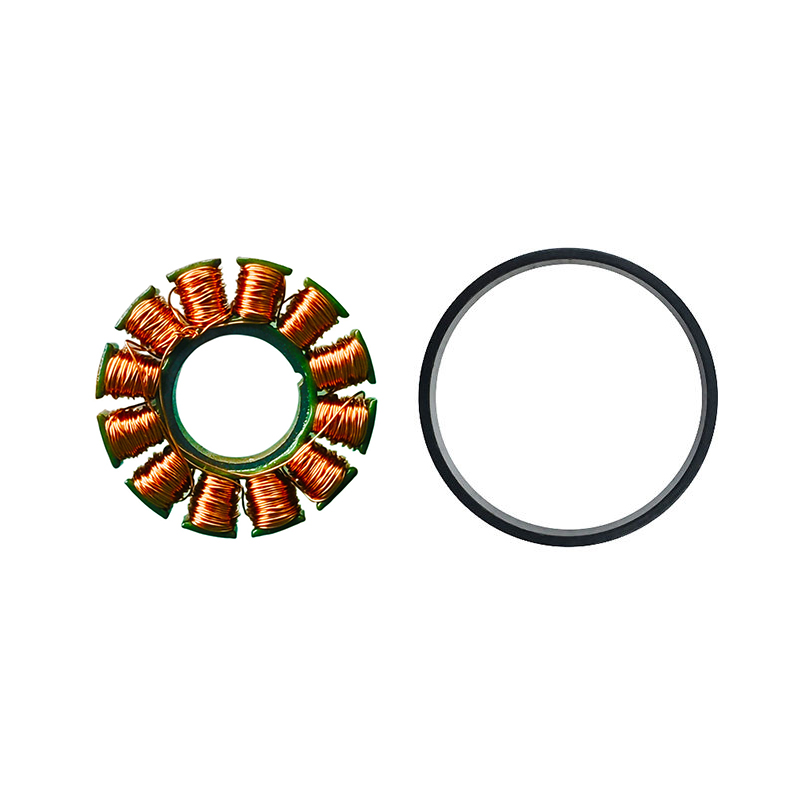

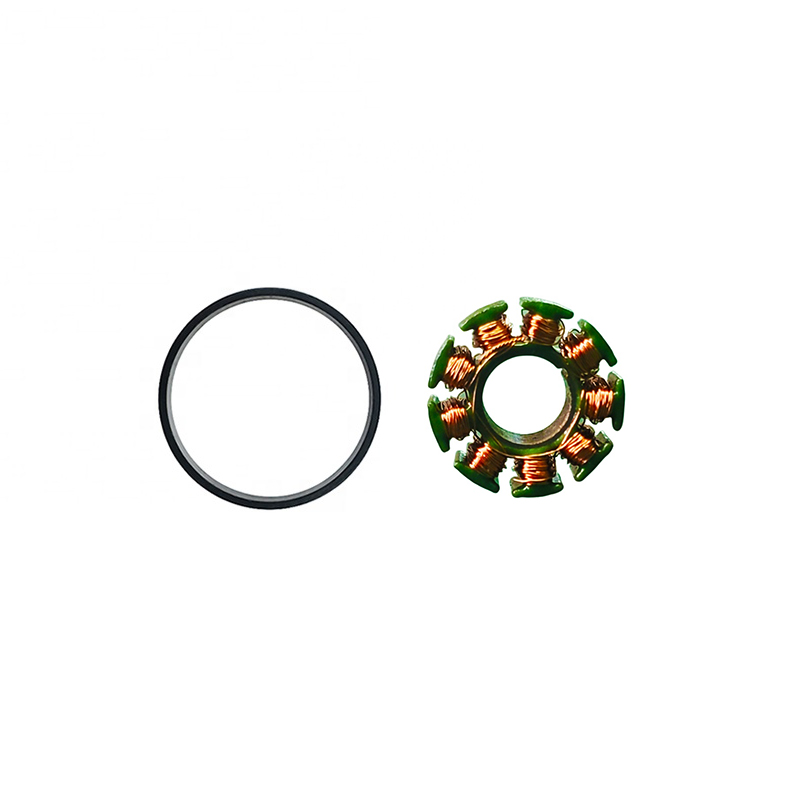

Before discussing frameless motors, let’s first take a look at the components that go into them. A frameless motor consists of a stator assembly and rotor assembly with permanent magnets. Hall effects may be offered as an option to provide feedback if an encoder is not selected for the application. The frameless motor does not include shaft, bearings, or end bells. The intent is that the motor will be directly integrated into the mechanical structure of the machine (the rotor is connected directly to the machine rotating shaft) leading to an optimized design, reduced footprint, and lighter machine weight.

Advantages of frameless motors

The performance advantage of a frameless motor is in the increased rigidity (stiffness) that it provides when designed into a machine. There are no mechanical elements between the motor and load (couplings, belts, pulleys, etc.) so dynamic performance is improved. Inertia matching is not as critical as the motor and load are now one inertial mass. In addition, because there are no mechanical parts to wear, the lifetime of the entire system is increased and maintenance costs are reduced.

Sizing a frameless motor

Sizing a frameless motor is the same as sizing a housed motor. You need to calculate speed and torque based on load inertia, acceleration, friction, etc. There seem to be more questions regarding what winding to choose from the many options. From experience, we advise that you look at your speed requirement and available voltage to the motor to approximate your motor’s required voltage constant (Ke/Vkrpm). The following is an example of how you can approximate your Ke:

Given:

- Required speed – 3,000 rpm

- Voltage – 120 VAC (168 VDC from the drive)

- Approximate Ke = Voltage/Speed (V/Krpm) = 168/3 = 56 V/Krpm

Typically, you would add in a 10 percent safety factor for any voltage drops, so make sure that after you select an appropriate frame size that meets your torque requirement, look for a winding that has a Ke that was no greater than 50 V/Krpm. Total voltage requirement needs to be addressed also and would take into account the required current (amps) for the application, the motors resistance, and the back electromotive force (BEMF) of the motor. The following continues with our example:

Given:

- Required speed – 3,000 rpm

- Required torque – 250 oz-in

- Voltage – 168 VDC

- Motor Ke – 50 V/Krpm

- Motor torque constant (Kt) – 60 oz-in/amp

- Motor resistance – 2 ohms

Total Voltage Requirement = IR+BEMF = (250/60 x 2) + 50 x 3 = 158 volts to meet your rpm requirement. Available voltage is 168 volts, so your selection thus far seems to be correct.

This example is meant to show a way to speed the selection of available windings when sizing your frameless motor. Other factors need to be taken into account such as thermal calculations involving dissipation and motor core losses. A review of the motor’s speed/torque curve should answer any concerns at this point in your motor selection.

Where frameless motors work best

In conclusion, frameless motors are an ideal solution for applications such as machine tools, centrifuges, mixers, winders, or any other application where mechanical elements represent additional maintenance costs and important loss of space. Parker offers frame sizes ranging from 32 to 254 mm in diameter providing torque from 6.3 to 13,000 oz-in and speeds up to 50,000 rpm. A variety of windings are available which will allow you to optimize your motor based on your power supply and application requirements.