Methods to reduce the stall current of brushless DC motors

In brushless DC motors, it is generally believed that the stall torque of the motor is the starting torque of the motor, but a detailed analysis shows that there are certain differences between the two.

Factors Affecting the Rated Current of Brushless DC Motors

The rated current of brushless DC motors is generally required by users, which involves the power of the DC power supply selected by the user and the amount of discharge (ampere-hour).

Analysis of the change of tooth flux density of brushless DC motor

To use tooth flux as the working flux of brushless DC motor, it is necessary to conduct some quantitative analysis on tooth magnetic induction intensity and find out some quantities related to tooth flux density and their mutual relationship so as to serve as the basis for judgment and design analysis when designing brushless DC motor.

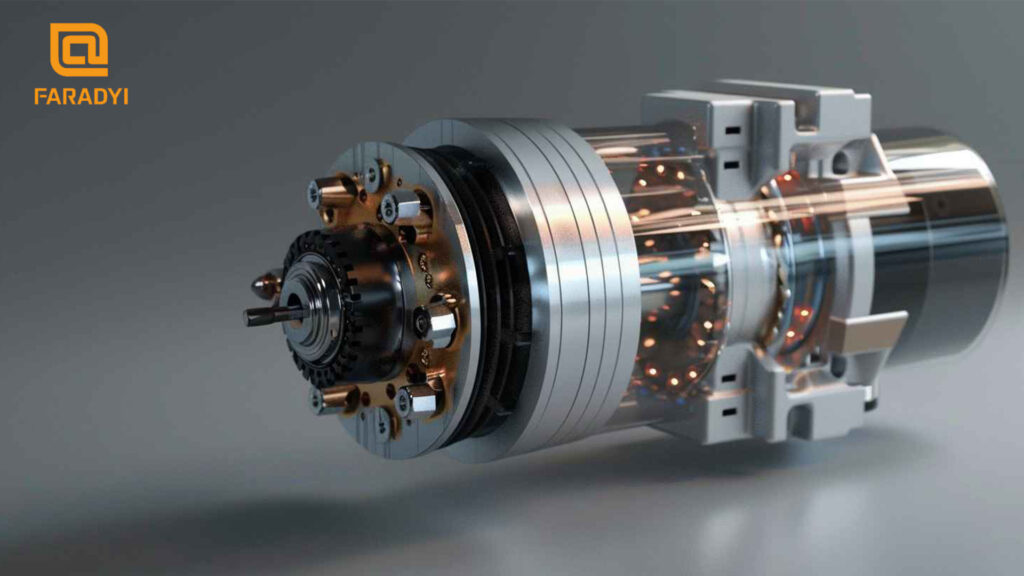

What are the advantages of brushless motors?

Brushless motors are composed of permanent magnet rotors, multi-pole winding stators, position sensors, etc. The position sensor changes the rotor position and commutates the current of the stator winding in a certain order (that is, it detects the position of the rotor pole relative to the stator winding, and generates a position sensing signal at a certain position. After being processed by the signal conversion circuit, it controls the power switch circuit and switches the winding current according to a certain logical relationship). The working voltage of the stator winding is provided by the electronic switch circuit controlled by the output of the position sensor.

Solutions To High Temperature Or Smoke Problems In Brushless Motors

In the process of using a brushless motor, we may encounter abnormalities such as high temperature or smoke. When such problems occur, we can check the motor from the following points. Let’s discuss them together today.

Why do brushless DC motors get hot? What causes this?

Causes of brushless DC motor overheating may include motor overload, low load power factor, too low speed, winding short circuit, abnormal voltage, unbalanced power supply, wiring errors, winding failure, bearing damage, excessive load, mechanical failure, frequent starting, High-temperature environments, dust and oil accumulation, and air duct obstructions require corresponding adjustments, repairs, and maintenance measures.

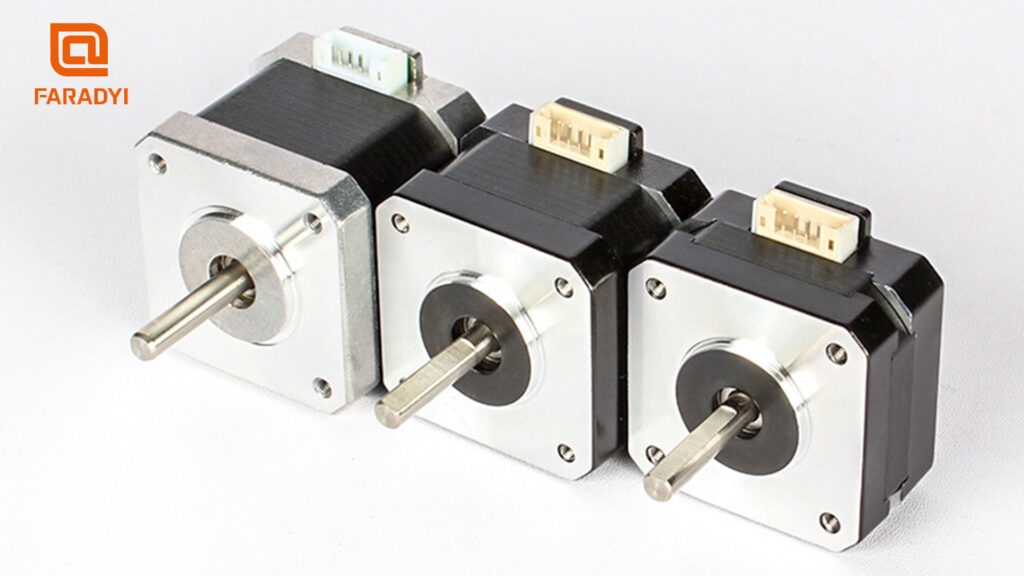

Advantages and Disadvantages of Two-Phase Hybrid Stepper Motors

The two-phase hybrid stepper motor is an open-loop control motor that converts electrical pulse signals into angular displacement or linear displacement. It is the main executive element in modern digital program control systems and is widely used.

Advantages and Disadvantages of Three-Phase Hybrid Stepper Motors

The three-phase hybrid stepper motor is an induction motor. Its working principle is to use electronic circuits to convert DC power into time-sharing power supply. The multi-phase timing controls the current and uses this current to power the stepper motor. The stepper motor In order to work normally, the driver is a multi-phase sequence controller that supplies time-sharing power to the stepper motor.

how to choose a stepper motor according to the use environment

The use of stepper motors is limited by working environmental conditions, including factors such as temperature, humidity, and dust. The standard models provided by the manufacturer are suitable for installation under good environmental conditions, but under special circumstances it is necessary to discuss the order with the manufacturer. Pay special attention to the insulation level, heat dissipation measures, rust prevention and dust prevention of the motor to ensure the normal operation of the stepper motor in various environments.

Comparison of square wave and sine wave drives for brushless DC motors

Compared with the sine wave drive, the brushless DC motor square wave drive has the advantages of simplicity, low cost, and high material utilization, but it has the disadvantages of large torque ripple. However, with good design and control, square wave drives can reach the level of brushed DC servo motors and are suitable for systems with average performance.