In brushless DC motors, it is generally believed that the stall torque of the motor is the starting torque of the motor, but a detailed analysis shows that there are certain differences between the two. The stall torque of the motor should be a torque applied to the motor, which gradually increases and eventually stops the motor. At this time, the torque output by the motor is equal to the braking torque applied to the motor. This torque can be considered as the stall torque of the motor. The current required by the motor at this time is the stall current of the motor.

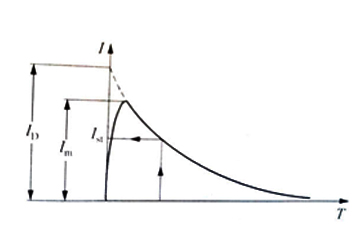

If the motor is stationary and a rated voltage is given to the brushless DC motor, the motor will start through a time transition process. During this time transition process, the current input to the motor is unequal.

Starting current transition process of brushless DC motor

The current waveform in the figure above is a single pulse wave, and its peak value is the current peak of the brushless motor. The current peak value should be less than the stall current of the motor. The larger the internal resistance of the motor, the smaller the stall current of the motor, and the softer the mechanical characteristics of the motor. The speed constant of the motor will become smaller, that is, the speed of the motor drops too fast after being stressed. Therefore, it is very important to use the stall current of the motor appropriately.

Some brushless DC motors have a large stall current. Once stalled, the motor will heat up quickly and burn easily. If the stall current of the motor is small, the starting current of the motor will also be small. If the starting current is too small to start the motor, it will be troublesome.

The following are several methods to reduce the stall current of brushless DC motors:

- (1) Increase the armature resistance of the motor, that is, the wire diameter of the motor should not be too large without affecting the motor performance and current density. When the motor needs to be powered by a battery or a rectifier power supply, the stall current of the motor needs to be considered in particular.

- (2) Reduce the diameter of the motor armature punching plate and increase the motor armature length, that is, reduce the motor’s slenderness ratio. The longer the motor armature, the larger the corresponding armature winding resistance, which can also appropriately limit the motor’s stall current and starting peak current.

- (3) Insert a current limiting resistor in series in the motor power supply circuit to prevent the stall current when the motor is stalled and the peak current when starting from being too large. However, the current limiting resistor consumes power and generates heat, so please note that.