From a principle and structural perspective, the body of a brushless DC motor essentially constitutes a permanent magnet synchronous motor, consisting of a stator with multiple phase windings and a rotor with permanent magnets. There are various structural forms of brushless DC motors, primarily including the following categories:

1. Radial Flux and Axial Flux Structures:

- Radial Flux Structure: The motor and the gap between the stator and rotor are cylindrical in shape, which is the most common configuration.

- Axial Flux Structure: The gap is perpendicular to the axis of rotation, often designed in a disc-shaped manner, appearing flat, and suitable for applications with axial size constraints.

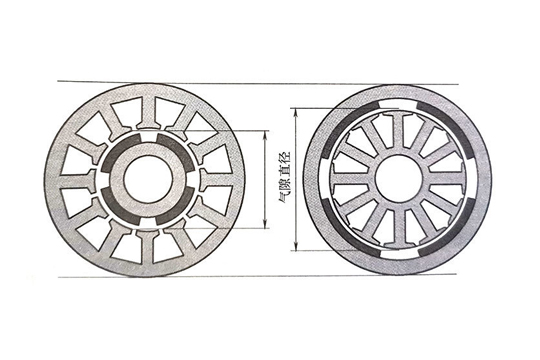

2. Outer Rotor and Inner Rotor Structures:

- Inner Rotor Structure: Suitable for applications requiring rapid acceleration and deceleration, with lower rotor inertia, good stator heat dissipation, and convenient installation.

- Outer Rotor Structure: Suitable for continuous operation at constant speed applications, with higher torque density but a more complex rotor support structure. Provides a larger air gap diameter under the same outer diameter, resulting in reduced length and weight.

3. Slotted and Slotless Structures:

- Slotted Structure: The stator has teeth and slots, suitable for general applications.

- Slotless Structure: The stator does not have teeth or slots, eliminating cogging, resulting in minimal torque ripple, smooth operation, low noise, and linear mechanical characteristics. However, it has a larger air gap, poor heat dissipation, and higher cost.

4. Integrated Structure Design:

- The drive can be integrated into the motor internally or combined with the driven mechanical components, reducing connections, simplifying the transmission chain, minimizing space requirements, reducing weight, and enhancing reliability.

Selection Methods:

- Choose the appropriate motor structure based on specific application requirements and performance criteria.

- Consider factors such as required speed, torque characteristics, and size limitations.

- Inner rotor structures are suitable for rapid acceleration/deceleration and high torque density requirements, while outer rotor structures are ideal for continuous operation at constant speed.

- Consider both slotted and slotless structures, weighing factors such as air gap diameter, heat dissipation, and cost.

- For specific applications, consider integrated designs to optimize system performance and reliability.

Conclusion:

For further information on brushless DC motors or technical support, feel free to contact us. Dongguan Falaide Motor Co., Ltd. is committed to providing you with high-performance, high-quality brushless DC motors and related solutions.