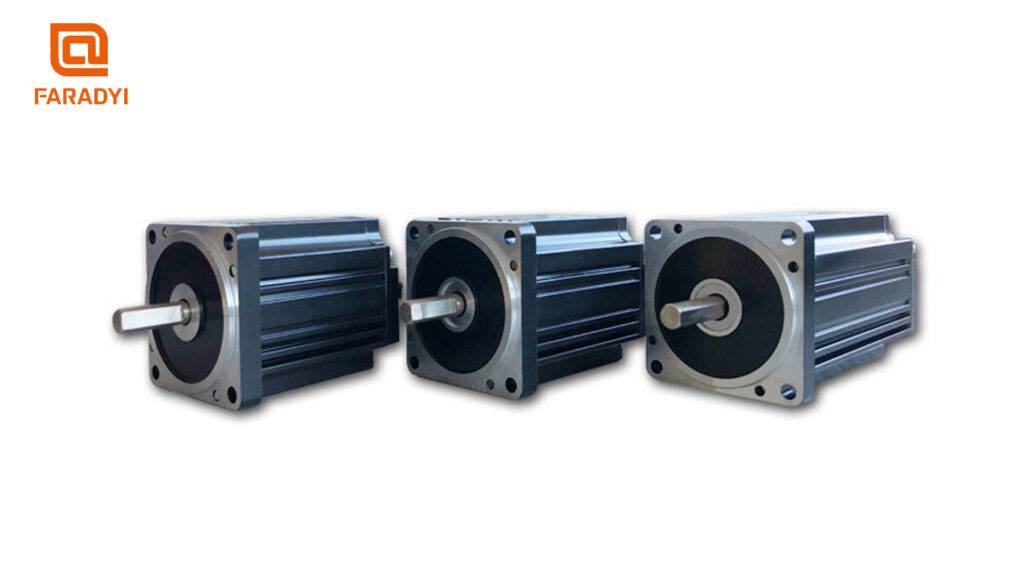

Advantages of Brushless DC Motors (BLDC)

Brushless DC motors (BLDC) offer simplicity in construction, reliability in operation, and ease of maintenance due to the absence of commutator, brushes, or slip rings, compared to traditional AC and DC motors.

Understanding Torque Ripple in Permanent Magnet Brushless DC Motors

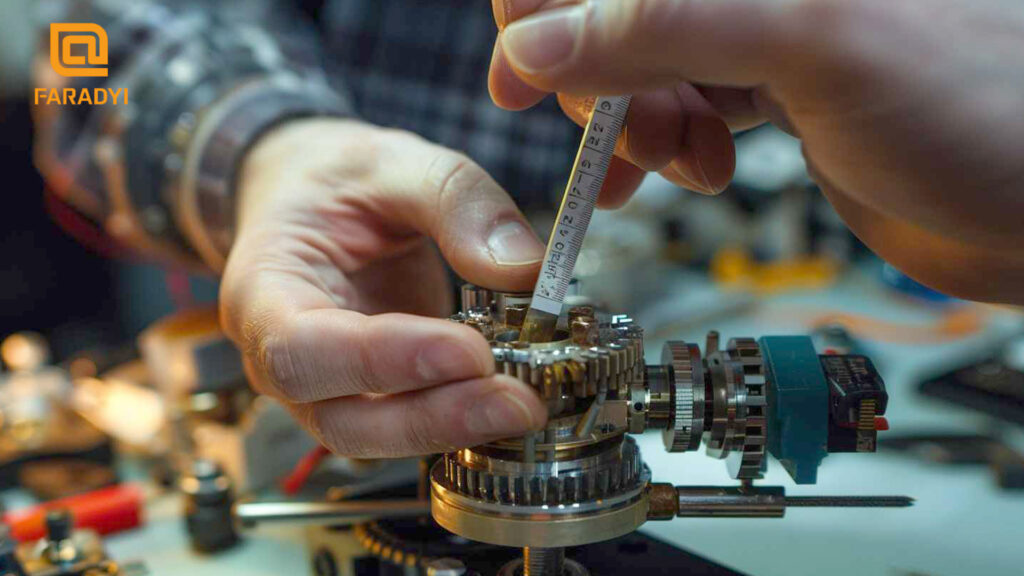

Torque ripple in permanent magnet brushless DC motors is a significant factor affecting motor performance and stability. Through optimization of motor design, improvement of control algorithms, and integration of monitoring devices, torque ripple can be effectively reduced, enhancing motor efficiency and stability to meet the requirements of various application scenarios.

Introduction To Permanent Magnet Brushless Dc Motor Control Circuit

The control circuit of a permanent magnet brushless DC motor serves as the core component of the motor controller, primarily responsible for decoding position signals, generating drive signals, controlling PWM chopping signals, speed detection and regulation, while also incorporating features such as over-current protection, soft-start, and bidirectional rotation control.

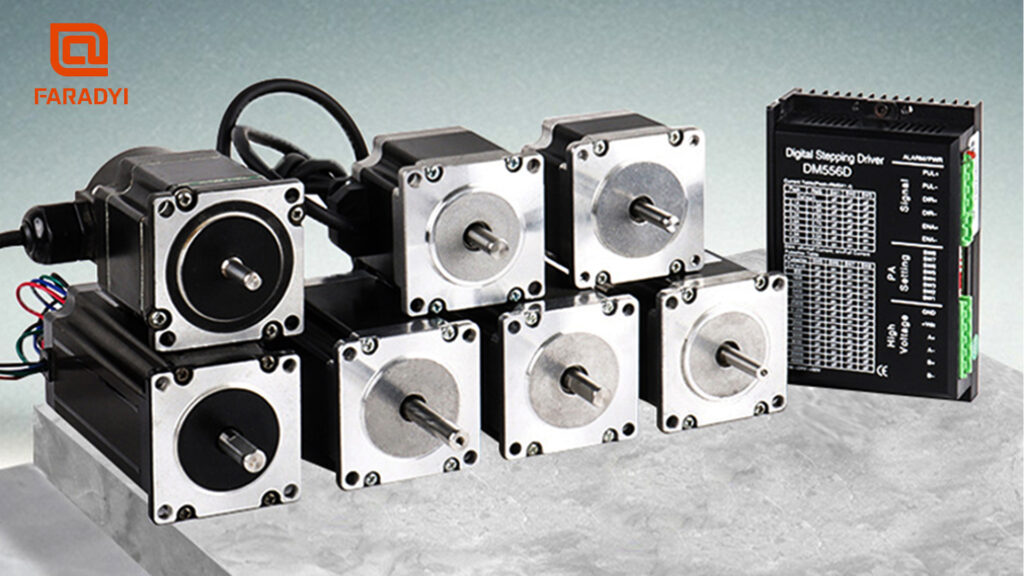

Application of Stepper Motors in Photocopiers

Stepper motors are widely used in the motors of photocopiers, which are one of the most common office automation machines. While photocopiers can utilize stepper motors, brushless motors, or DC motors, this article focuses on the application of stepper motors in photocopiers.

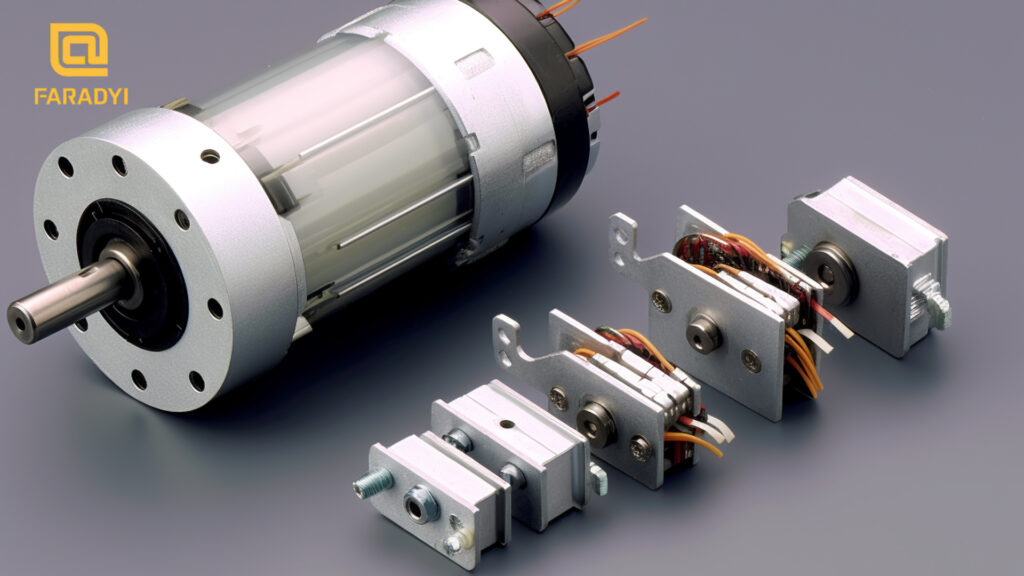

Introduction to CAD Software for Brushless DC Motors

The article emphasizes how CAD technology can accelerate the design process and improve design quality, while emphasizing the importance of designers’ basic theoretical knowledge and experience.

Design technical requirements and process of brushless DC motor

Design technical requirements and typical design process of brushless DC motor.For further information on brushless DC motor design or technical support, please feel free to contact us.

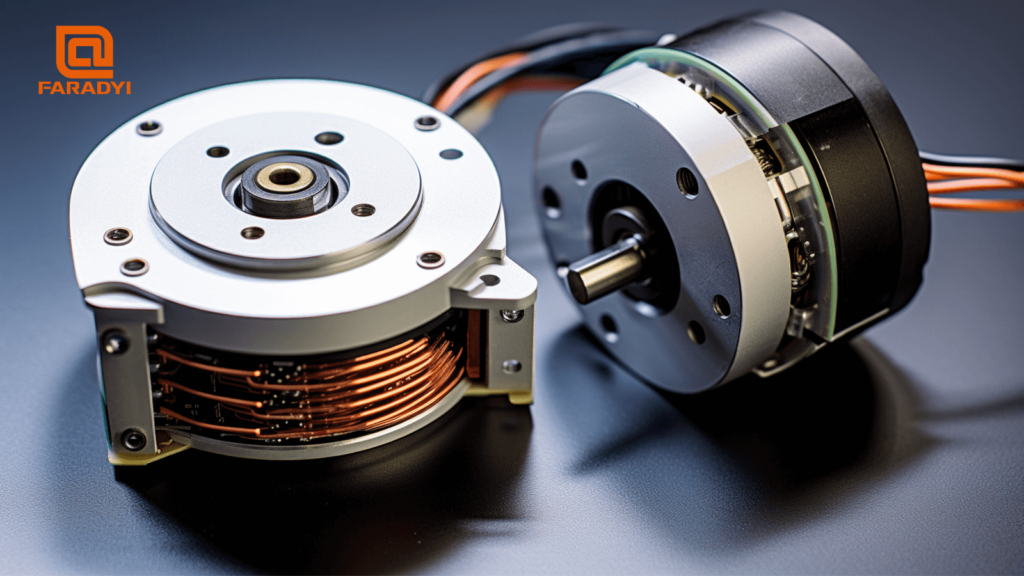

Selection Methods for Brushless DC Motor Body Structure

Selection of the brushless DC motor body structure should be based on a comprehensive consideration of specific application needs and performance requirements. Choosing the right structure can maximize design requirements, improve motor efficiency, and enhance reliability.

Technical Standards and Key Parameters of Servo Control Systems

The technical standards and key parameters of servo control systems play a crucial role in ensuring the efficient and reliable operation of servo systems in various applications. The proper setting and adjustment of these parameters are essential to achieve optimal performance and meet the specific requirements of different servo control applications.

Differences in Characteristics and Functions Between DC and AC Servo Motors

The differences in characteristics and functions between DC and AC servo motors reflect their unique strengths and weaknesses. AC servo motors are suitable for applications requiring soft characteristics and broad use, while DC servo motors are known for their precise speed control, smooth operation, and efficiency. As technology continues to advance, both types of motors are expected to see further improvements, leading to more efficient and reliable motor systems.

How to Start and Use Brushless Motors

Most brushless motors on the market use Hall sensors to sense position and are controlled by sinusoidal wave controllers for normal operation.